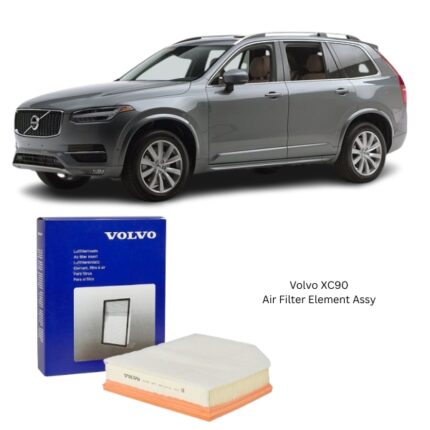

Get Volvo XC90 Air Filter Element Assy 31370089 in Kenya

The Air Filter Element Assembly is an essential component within a vehicle’s engine intake system, playing a critical role in maintaining engine health, ensuring optimal combustion, and protecting internal engine components from contaminants. Its primary function is to clean the air entering the engine by trapping dust, dirt, pollen, debris, and other airborne particles, preventing them from entering the combustion chamber where they could cause wear, damage, or performance inefficiencies. Without a properly functioning air filter element, the engine’s performance, fuel efficiency, and lifespan could be significantly compromised.

Function and Importance

In an internal combustion engine, air is as crucial as fuel for the combustion process. The air filter ensures that only clean air reaches the combustion chamber. By filtering out harmful particles, it prevents abrasive materials from scratching or wearing down the surfaces of the cylinders, pistons, and other internal parts. Additionally, clean air supports efficient combustion, helping maintain power output, fuel economy, and emissions compliance.

The Air Filter Element Assembly is often made from pleated paper, cotton, or synthetic fiber materials designed to maximize the filtration surface area while allowing adequate airflow. The filtration medium is typically held in a frame made from rubber, plastic, or metal to ensure a secure fit in the housing and to prevent unfiltered air from bypassing the filter.

Design and Construction

The assembly generally consists of:

-

Filter Media – The core of the assembly, made from specialized materials that balance filtration efficiency with airflow. The pleated design increases surface area, allowing for better dirt retention without restricting air supply.

-

Support Frame – Provides structural rigidity, ensuring the filter maintains its shape even under the suction pressure of the intake system.

-

Seal or Gasket – Usually made of rubber or foam, the seal prevents unfiltered air from leaking around the edges of the filter.

Different vehicles have variations in shape and size—some air filters are rectangular or square, while others may be circular or conical—depending on the engine layout and air intake design.

Operation

When the engine runs, the intake system draws in air from the outside environment. This air passes through the Air Filter Element Assembly before reaching the throttle body or carburetor, and subsequently the combustion chamber. The filter traps microscopic and visible contaminants in its fibers while allowing clean air to pass through freely. Over time, as contaminants accumulate, the filter’s airflow capacity may reduce, signaling the need for replacement.

Benefits of a Properly Functioning Air Filter Element

-

Engine Protection – Prevents dirt and debris from entering and damaging internal engine components.

-

Improved Performance – Ensures a steady supply of clean air, supporting efficient combustion and maintaining optimal horsepower.

-

Better Fuel Economy – An unrestricted airflow helps maintain the ideal air-to-fuel ratio, reducing fuel wastage.

-

Lower Emissions – Clean air enables complete combustion, minimizing unburned fuel and harmful exhaust gases.

-

Extended Engine Life – Reduced wear from contaminants prolongs the overall service life of the engine.

Signs the Air Filter Element Needs Replacement

-

Reduced Acceleration or Power Loss – Dirty filters restrict airflow, causing sluggish performance.

-

Decreased Fuel Efficiency – The engine compensates for reduced airflow by burning more fuel.

-

Black Smoke from Exhaust – Incomplete combustion due to restricted air supply can cause excessive soot.

-

Unusual Engine Sounds – Whistling or coughing noises can occur when the air intake struggles for flow.

-

Visual Inspection – A visibly dirty or clogged filter is an immediate indication for replacement.

Maintenance and Replacement

The air filter is a consumable part that requires regular inspection and replacement as part of scheduled maintenance. Replacement intervals vary depending on driving conditions:

-

Normal Conditions – Every 12,000 to 15,000 kilometers or as specified by the vehicle manufacturer.

-

Dusty or Harsh Conditions – More frequent replacements may be necessary, sometimes every 5,000 to 8,000 kilometers.

Replacement involves removing the old filter from its housing, cleaning out any debris from the air box, and installing a new filter element with the seal properly aligned.

Material and Technology Advancements

Modern Air Filter Element Assemblies have evolved to incorporate advanced filter media that improve dust-holding capacity and airflow. Multi-layer synthetic fibers, high-efficiency paper blends, and even oiled cotton materials are used to balance performance and longevity. Some premium filters are washable and reusable, though most are designed for single-use to ensure maximum filtration consistency.

Impact of Neglecting Air Filter Maintenance

Failing to replace a dirty air filter can have several negative consequences:

-

Engine Wear – Dust particles entering the engine can cause scoring and wear in cylinders and bearings.

-

Poor Combustion – Reduced air supply can upset the air-to-fuel ratio, leading to incomplete combustion and carbon buildup.

-

Sensor Damage – Dirt passing through may foul sensors like the Mass Air Flow (MAF) sensor, affecting engine control.

-

Increased Emissions – Incomplete combustion leads to higher hydrocarbon and carbon monoxide emissions.

-

Overheating – Restricted airflow can cause the engine to work harder, generating more heat.

Environmental Considerations

Many Air Filter Element Assemblies are disposable, so proper disposal is important to minimize environmental impact. Some manufacturers offer eco-friendly filters made from biodegradable materials. Others provide reusable high-performance filters that can be cleaned and re-oiled, reducing waste over time.

Applications

The Air Filter Element Assembly is used in:

-

Passenger Cars – Sedans, hatchbacks, SUVs, and coupes for daily road use.

-

Commercial Vehicles – Trucks, buses, and delivery vans.

-

Off-Road and Agricultural Equipment – Where dust and debris levels are especially high.

-

High-Performance Vehicles – Where optimized airflow is crucial for performance.

Quality Standards

High-quality Air Filter Element Assemblies adhere to industry standards such as ISO/TS 16949 and meet or exceed OEM specifications. This ensures they provide:

-

Correct fitment for the designated housing.

-

Adequate filtration efficiency, often above 99%.

-

Structural durability under varying temperatures and pressures.

-

Reliable sealing to prevent unfiltered air bypass.

Follow us on Facebook for More Parts.

Reviews

Clear filtersThere are no reviews yet.