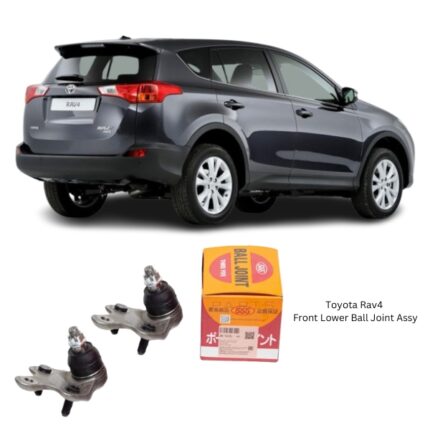

Get Toyota Rav4 Front Lower Ball Joint Assy SB-T432 in Kenya

The Front Lower Ball Joint Assembly is a vital component of a vehicle’s front suspension system. Positioned at the lower connection point between the control arm and the steering knuckle, it serves as a pivot that allows the wheels to move up and down with suspension travel, while also turning left or right with steering input. Acting much like a human joint, the ball joint enables multi-directional movement, supporting both vertical load and lateral motion.

Constructed for strength, durability, and performance, this assembly ensures proper wheel alignment, optimal handling, and a smooth ride. Whether you’re navigating pothole-ridden roads or cruising on smooth highways, the front lower ball joint absorbs shocks and manages the mechanical stress involved in daily driving.

Key Features

1. Forged Housing for Maximum Strength

The main body of the ball joint is made from high-strength forged steel or iron, providing exceptional toughness and resistance to deformation. This material selection ensures that the joint can handle high stress and load conditions without compromising structural integrity, even under heavy braking or uneven road surfaces.

2. Precision-Hardened Ball Stud

At the heart of the assembly is a chrome-hardened steel ball stud, engineered for maximum wear resistance and low friction. The stud’s spherical design allows for rotational movement inside the socket, while its hardened surface resists pitting, scoring, and corrosion. This ensures long-term performance and smoother suspension articulation.

3. Advanced Polymer Bearing or Metal-on-Metal Design

Depending on the design, the ball joint may use a polymer bearing liner or a metal-on-metal contact surface, both of which are engineered to reduce friction and wear. Polymer-based liners offer a quieter and smoother operation, while metal-on-metal configurations provide increased durability and load capacity, especially for rugged terrain or commercial use.

4. High-Quality Dust Boot

A protective rubber or thermoplastic boot seals the ball joint, shielding it from moisture, dirt, road salts, and other contaminants. This sealing mechanism is vital for preserving internal lubrication and preventing premature wear. The boot is often reinforced with a spring or clamp to ensure a tight seal during dynamic suspension movement.

5. Pre-Greased or Greaseable Design

Some models come pre-lubricated with high-temperature synthetic grease for lifetime maintenance-free operation. Others feature a grease fitting (Zerk fitting), allowing technicians to periodically add fresh lubricant during scheduled servicing. Greaseable designs are favored in high-demand or off-road applications where extra care can prolong service life.

6. Anti-Corrosion Coating

To extend service life, many ball joints feature surface treatments such as black oxide, zinc plating, or phosphate coatings. These finishes protect against corrosion from water, salt, and grime, especially in regions with harsh weather or off-road exposure.

7. OE-Style Fit and Finish

Designed to match the dimensions and performance specifications of the original factory component, the ball joint ensures a precise fit with existing control arms and steering knuckles. OE-style taper and threading make installation straightforward, reducing labor time and the need for modifications.

8. Hardware Included

Many ball joint kits come complete with essential hardware such as:

-

Mounting bolts or nuts

-

Cotter pin or locking clip

-

Grease nipple (if greaseable)

-

Dust boot and retaining ring

This all-in-one package makes installation more efficient and ensures all parts are correctly matched for compatibility.

Performance and Benefits

1. Enhanced Steering Response

A well-functioning ball joint minimizes steering play and contributes to crisp, accurate steering control. It maintains correct steering geometry, allowing the vehicle to respond predictably to driver input.

2. Smoother Suspension Movement

Because the ball joint enables up-and-down wheel motion, it plays a crucial role in absorbing road imperfections. Replacing a worn joint restores suspension fluidity, leading to a smoother ride and less stress on surrounding components.

3. Improved Tire Wear

Worn or loose ball joints can cause misalignment, resulting in uneven tire wear. Installing a new front lower ball joint helps maintain proper camber and caster angles, extending the life of your tires and reducing rolling resistance.

4. Noise Reduction

A worn ball joint may produce clunking or knocking noises during turns, over bumps, or during braking. A new joint eliminates these sounds, providing a quieter and more refined driving experience.

5. Safety and Control

Compromised ball joints can lead to unpredictable steering behavior, reduced handling, and even loss of control in extreme cases. Replacing the front lower ball joint ensures safer operation, particularly during emergency maneuvers or high-speed driving.

Signs of a Failing Front Lower Ball Joint

-

Clunking or Knocking Noise: Especially when turning or going over speed bumps.

-

Loose or Wandering Steering: Increased play or drift in the steering wheel.

-

Uneven Tire Wear: Particularly on the inside or outside edge.

-

Vibration in Steering Wheel: Felt during acceleration, braking, or cornering.

-

Excessive Suspension Movement: Ball joint looseness can result in poor suspension control.

Prompt replacement is essential to prevent further damage to suspension components and maintain vehicle safety.

Installation Notes

-

Use appropriate tools such as a ball joint press or separator to remove the old unit.

-

Torque all mounting hardware to manufacturer specifications.

-

Ensure the dust boot is seated properly to avoid contamination.

-

After installation, it’s recommended to perform a wheel alignment to maintain proper suspension geometry.

-

Inspect adjacent components such as the control arm, bushings, and sway bar links for wear during replacement.

Maintenance Tips

-

For serviceable units, reapply high-temperature grease during every major service interval or after off-road driving.

-

Avoid high-pressure washing around the joint area to preserve the integrity of the dust boot.

-

Periodically inspect the boot for cracks or tears and replace if necessary.

-

Listen for early warning sounds when driving over rough surfaces or turning sharply.

Follow us on Facebook for more parts.

Reviews

Clear filtersThere are no reviews yet.