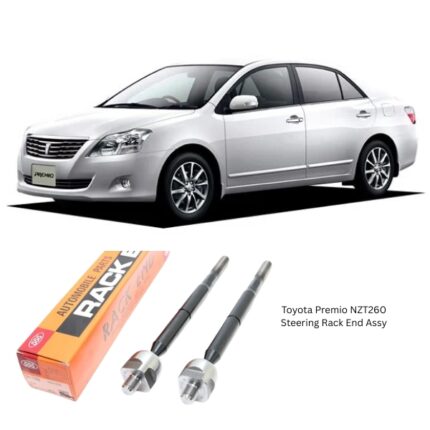

Get Toyota Premio NZT260 Steering Rack End Assy SR-T360 in Kenya

The Steering Rack End Assembly SR-T360 is a critical component in the steering system of a vehicle, designed to ensure precise steering control and safe handling under a wide range of driving conditions. Also known as the inner tie rod, the rack end links the steering rack (or rack and pinion gear) to the outer tie rod, which in turn connects to the steering knuckle. This assembly plays a crucial role in transferring driver input from the steering wheel to the front wheels.

A high-quality rack end assembly like the SR-T360 is engineered for performance, durability, and a secure fit. Whether installed as part of routine maintenance or to address handling issues, it restores steering accuracy, minimizes play, and contributes to safe, stable driving.

Function of the Steering Rack End Assembly

The primary function of the steering rack end is to transmit steering force from the steering gear to the steering knuckle via the outer tie rod end. It allows for both rotational and linear movement of the steering system while maintaining alignment and integrity under dynamic load conditions.

Key responsibilities of the SR-T360 rack end include:

-

Transmitting Force: It converts the rotational motion of the steering wheel into lateral movement of the wheels, enabling the vehicle to turn left or right.

-

Absorbing Road Forces: It helps absorb and manage minor shocks and vibrations coming from the wheels, protecting the steering rack and maintaining a smooth driving experience.

-

Maintaining Alignment: It keeps the steering system aligned by resisting excessive play and ensuring that toe settings remain consistent.

-

Allowing Controlled Articulation: As part of a moving linkage, it permits vertical and horizontal motion to accommodate road irregularities while maintaining steering precision.

The proper function of the rack end is essential for maintaining sharp steering feedback, proper alignment, and long-term suspension integrity.

Construction and Materials

The SR-T360 Steering Rack End Assembly is constructed using high-strength, corrosion-resistant materials designed to endure high load-bearing conditions, frequent directional changes, and exposure to environmental contaminants.

Main Components of the Assembly:

-

Inner Ball Joint:

-

Allows for angular articulation and transmits motion from the steering rack to the outer tie rod.

-

Precision-machined for low friction and high durability.

-

Encased in a grease-filled housing to minimize wear.

-

-

Threaded Shaft:

-

One end connects securely to the steering rack, while the other threads into the outer tie rod.

-

Manufactured with rolled threads for improved strength and longevity.

-

-

Protective Boot (optional but often paired):

-

A dust boot seals the joint from water, debris, and road contaminants, preserving the life of the internal components.

-

-

Locking Washer or Retaining Clip:

-

Prevents loosening during operation and ensures secure installation.

-

-

Coatings and Treatments:

-

Treated with anti-corrosion plating (such as zinc or phosphate coating) for added durability against rust and chemical exposure.

-

The SR-T360 is engineered to meet or exceed OEM performance standards, ensuring dependable operation even in high-stress environments.

Compatibility and Application

While the SR-T360 is a universal part number used across multiple applications, it is designed with precision tolerances for vehicles that require a specific rack end length, thread pitch, and articulation angle.

Before installation, it is essential to verify:

-

Thread Size and Pitch

-

Overall Length

-

Inner Ball Joint Diameter

-

Thread Direction (right-hand or left-hand)

-

Compatibility with outer tie rod and steering rack design

Using the correct rack end ensures optimal alignment, smooth installation, and long-term durability.

Performance Benefits

Installing a new SR-T360 Steering Rack End Assembly provides several performance and safety advantages:

-

Enhanced Steering Precision:

-

Reduces play and slack in the steering system for tighter control and faster response.

-

-

Improved Vehicle Alignment:

-

Maintains proper toe angle, reducing uneven tire wear and improving handling consistency.

-

-

Reduced Noise and Vibration:

-

Eliminates clunks, knocks, or looseness from worn ball joints or damaged threads.

-

-

Increased Suspension Longevity:

-

Supports uniform movement across the steering system, easing stress on connected components like the steering knuckle and outer tie rod ends.

-

-

Better Road Feedback:

-

Provides a direct, predictable feel through the steering wheel, boosting driver confidence, especially at higher speeds.

-

Signs of a Failing Rack End

A worn or damaged steering rack end can compromise handling, increase stopping distances, and lead to unsafe driving conditions. Recognizing early symptoms helps prevent further damage.

Common Signs Include:

-

Steering Play or Looseness:

-

Excessive movement in the steering wheel before the wheels respond.

-

-

Clunking or Knocking Noises:

-

Noticeable during turns or over bumps, especially from the front suspension area.

-

-

Uneven or Rapid Tire Wear:

-

Misalignment caused by a failing rack end can wear out tire edges prematurely.

-

-

Steering Wheel Vibration:

-

A loose or worn rack end can transmit road vibration to the driver.

-

-

Pulling to One Side:

-

Indicates inconsistent steering force or a shift in alignment geometry.

-

Regular inspection of the steering linkage during service intervals helps catch rack end issues early.

Installation Overview

Installing the SR-T360 Steering Rack End Assembly requires mechanical knowledge and proper tools. The process involves removing the old rack end and replacing it with the new unit, followed by a precise wheel alignment.

Basic Installation Steps:

-

Lift the Vehicle and Remove the Front Wheels

-

Detach the Outer Tie Rod End:

-

Use a puller if needed to separate it from the knuckle.

-

-

Loosen the Lock Nut and Unscrew the Old Rack End:

-

Unthread it from the steering rack with the correct tool.

-

-

Install the SR-T360 Rack End:

-

Thread it into place and secure using a lock washer or clip.

-

-

Reconnect the Outer Tie Rod End:

-

Torque it to specifications.

-

-

Reinstall Wheels and Perform Wheel Alignment:

-

Alignment is critical to avoid steering issues and tire wear.

-

Professional installation is recommended to ensure safety and alignment precision.

Maintenance and Longevity

To maximize the life of the SR-T360 Rack End Assembly:

-

Inspect during Routine Service:

-

Check for looseness, damage, or torn boots every 10,000–15,000 kilometers.

-

-

Keep the Joint Protected:

-

Ensure dust boots are intact and that the joint is properly lubricated.

-

-

Avoid Road Impacts:

-

Potholes and curb hits can damage suspension components, including the rack end.

-

-

Monitor Tire Wear Patterns:

-

Uneven wear may be a sign of misalignment or component play.

-

-

Replace in Pairs:

-

If one rack end is worn, the other may soon follow.

-

Follow us on Facebook for more parts.