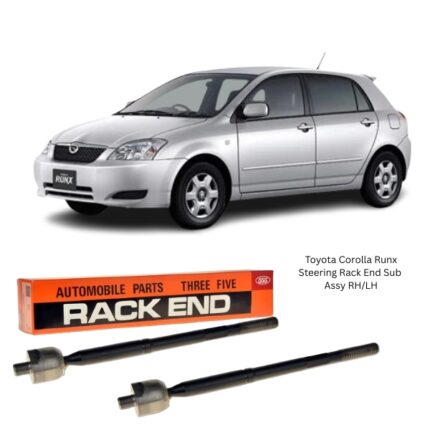

Get Toyota Corolla Runx/Allex Steering Rack End Sub Assy RH/LH SR-3640 in Kenya

The Steering Rack End Sub Assembly RH/LH is a crucial component of the steering system that plays a direct role in translating steering wheel input into lateral wheel movement. Located at each end of the steering rack—on both the right-hand (RH) and left-hand (LH) sides—it serves as the connecting link between the inner steering gear mechanism and the outer tie rod ends. This component ensures accurate wheel articulation, responsive handling, and safe directional control of the vehicle.

Engineered to perform under constant stress, the rack end assembly is subject to lateral forces, road vibrations, and steering torque. It must be strong enough to withstand these conditions while maintaining tight tolerances to prevent steering play or misalignment. The assembly consists of a ball-and-socket joint housed in a rigid shaft, designed to move freely while holding precise alignment.

Component Breakdown and Construction

The Steering Rack End Sub Assembly is made from robust materials to ensure durability, performance, and safety. Its core components include:

-

Inner Tie Rod Shaft: A steel rod that threads directly into the steering rack housing. It extends outward to connect to the outer tie rod end.

-

Ball Socket Joint: Allows for multidirectional movement, enabling the tie rod to pivot during suspension articulation and steering motion.

-

Threaded Ends: One end is threaded into the steering rack housing, while the outer end allows secure attachment to the outer tie rod via a locking nut.

-

Protective Boot (Bellows Compatibility): Often used with a rubber bellows or boot to shield the ball joint from contaminants such as dust, water, and debris.

-

Anti-Corrosion Coating: Many assemblies include zinc or phosphate coatings to resist rust and prolong service life.

Materials typically include hardened steel alloys for the shaft and ball socket, which are heat-treated for strength and wear resistance. Premium versions may feature low-friction surfaces or greased-for-life designs that enhance steering feel and durability.

Function and Role in the Steering System

The Steering Rack End Sub Assembly RH/LH performs the following critical tasks:

-

Transmits Steering Input: It converts the linear motion of the steering rack into lateral movement that turns the front wheels.

-

Maintains Alignment: By holding the tie rod in the correct position relative to the suspension, it helps maintain camber and toe settings.

-

Absorbs Suspension Travel: Its flexible pivot design allows for slight angular adjustments as the suspension compresses and rebounds.

-

Preserves Steering Precision: Works with the outer tie rod and steering knuckle to deliver consistent and responsive steering behavior.

-

Balances Load Between Wheels: Ensures synchronized motion between left and right steering mechanisms.

Because this component links the steering gear to the wheels, its condition directly affects handling, tire wear, and overall vehicle safety.

Advantages of a High-Quality Rack End Sub Assembly

A well-manufactured Steering Rack End Sub Assembly RH/LH provides several performance and longevity advantages:

-

Responsive Handling: Maintains steering sharpness and ensures quick response to driver input.

-

Durable Construction: Designed to resist bending, breakage, and wear under load.

-

Reduced Vibrations: Properly functioning joints isolate road shocks and prevent vibrations from reaching the steering wheel.

-

Enhanced Safety: Prevents steering play or looseness, which could lead to dangerous loss of control.

-

Alignment Stability: Helps retain correct suspension geometry over time, contributing to even tire wear and improved fuel economy.

Common Symptoms of Wear or Failure

Due to its constant exposure to mechanical stress and environmental elements, the Steering Rack End Sub Assembly can wear out over time. Symptoms of a failing rack end include:

-

Loose Steering Feel: Excessive play in the steering wheel, often caused by a worn ball socket joint.

-

Clunking or Knocking Sounds: Audible noise during steering or while driving over rough surfaces, indicating looseness or damage in the joint.

-

Uneven Tire Wear: Improper toe alignment due to rack end movement can result in rapid or uneven tread wear.

-

Steering Wander: Difficulty maintaining a straight path on flat roads due to shifting tie rod alignment.

-

Vehicle Pulling: A failing rack end can affect alignment, causing the vehicle to pull to one side.

-

Vibration in the Steering Wheel: Worn or misaligned components transmit road vibration to the steering column.

-

Visual Damage or Corrosion: Cracks, worn threads, rust, or torn protective boots can be visible during inspection.

Addressing these signs early helps prevent steering system failure and associated safety risks.

Installation and Replacement Process

Replacing the Steering Rack End Sub Assembly RH/LH requires precision and alignment expertise. Below is a general guide:

-

Lift and Secure the Vehicle: Use jack stands to elevate and support the front of the vehicle.

-

Remove the Wheel: For access to the steering knuckle and tie rod.

-

Loosen the Lock Nut: Detach the outer tie rod end from the inner rack end.

-

Unthread the Rack End: From the steering rack using a specialty inner tie rod tool.

-

Install the New Assembly: Thread the new rack end into the steering rack housing and tighten to torque specifications.

-

Reconnect the Outer Tie Rod End: Adjust and tighten the lock nut.

-

Install New Boot if Needed: Ensure proper sealing to protect the joint.

-

Perform Wheel Alignment: Critical to restore correct toe and steering angles after installation.

Proper tools, torque values, and post-installation alignment are essential for safety and optimal steering performance.

Maintenance and Care Tips

While generally low-maintenance, regular inspection of the rack end assembly ensures long service life:

-

Check for Play: During routine suspension checks, test the rack end for movement by rocking the wheel side to side.

-

Inspect Dust Boots: Torn or missing boots expose joints to contaminants, leading to premature wear.

-

Monitor Tire Wear: Unusual patterns may indicate steering or alignment problems.

-

Lubrication (If Serviceable): Some rack ends feature grease fittings; others are sealed. Always follow manufacturer guidance.

-

Replace in Pairs: If one side is worn, the other is likely close behind. Replacing both RH and LH rack ends together ensures balanced steering response.

Routine checks help avoid sudden failures and preserve consistent vehicle control.

Importance of Fitment Accuracy

The Steering Rack End Sub Assembly must match vehicle specifications for thread size, length, ball joint orientation, and travel limits. Improper fitment may result in:

-

Incorrect toe angles

-

Reduced turning radius

-

Binding or restricted movement

-

Steering instability or vibration

OEM-quality or direct-fit aftermarket parts provide assurance of proper performance and compatibility.

Follow us on Facebook for more parts.