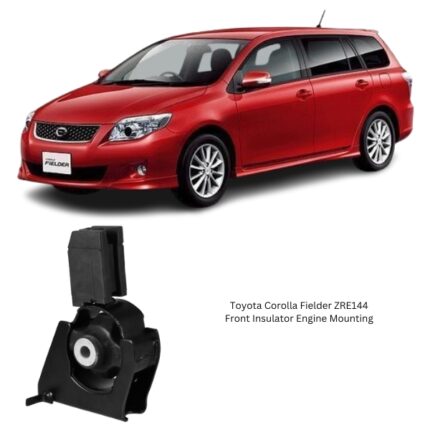

Get Toyota Corolla Fielder ZRE144 Front Insulator Engine Mounting 12361-21100 in Kenya

The Front Insulator Engine Mounting is a crucial part of a vehicle’s engine support system. It plays a dual role—serving as both a structural anchor and a vibration isolator—by firmly securing the engine to the vehicle’s chassis while absorbing the natural vibrations and torque reactions that occur during engine operation. This mounting component ensures smoother driving, improved ride comfort, and extended longevity of both the engine and related drivetrain components.

Positioned at the front end of the engine bay, this insulator mount is strategically placed to counteract the forward-rearward rocking forces generated by engine acceleration, braking, or load changes. It works in tandem with other engine mounts (rear, left-hand, and right-hand mounts) to maintain the proper positioning and alignment of the engine and transmission.

Primary Function and Purpose

The front insulator engine mount is designed to fulfill several essential tasks:

-

Structural Support: It bears a portion of the engine’s weight, particularly the front section, and helps anchor the engine to the subframe or crossmember.

-

Vibration Isolation: It absorbs and dampens engine vibrations caused by combustion, preventing them from being transmitted into the passenger cabin.

-

Torque Reaction Control: It reduces engine movement caused by torque loads during sudden acceleration, gear shifts, or abrupt braking.

-

Engine Alignment: Maintains proper alignment of the engine and drivetrain components for optimal mechanical performance.

-

System Protection: Reduces wear and tear on adjacent systems such as the exhaust manifold, radiator hoses, driveshafts, and electrical harnesses.

These combined functions help deliver a quieter, more refined driving experience while preserving engine integrity.

Design and Construction

The Front Insulator Engine Mounting is built to be durable, heat-resistant, and vibration-absorbing. It consists of several parts that work in unison to provide mechanical support and noise isolation.

Key Components Include:

-

Metal Bracket or Housing

Typically made from forged steel, cast aluminum, or high-strength stamped steel, this component provides structural rigidity and is bolted directly to the engine or subframe. -

Rubber or Polyurethane Elastomer

The core insulator is formed from high-grade rubber or synthetic materials and is vulcanized to the metal bracket. This component flexes to absorb vibrations and engine movement. -

Central Bushing or Sleeve

A metal sleeve runs through the rubber core to allow for the insertion of a bolt that secures the mount in place while allowing limited engine movement. -

Hydraulic Chamber (in some variants)

Advanced engine mounts include a fluid-filled chamber that enhances vibration damping, particularly during idle or light-load conditions. -

Anti-Corrosion Coating and Heat Shield (optional)

Coatings and shields help protect the mount from oil, coolant, road salt, and excessive heat emitted by engine or exhaust components.

The combination of materials provides long-term durability and effective vibration control across a range of operating temperatures and load conditions.

Performance Features

The front insulator engine mount is engineered to meet high-performance standards. Its key features include:

-

Load Resistance: Withstands both the static weight of the engine and the dynamic forces generated during vehicle operation.

-

Vibration Damping: Absorbs a wide range of frequencies to ensure smooth and quiet engine operation.

-

Fatigue Resistance: Endures thousands of compression-extension cycles without degradation.

-

Thermal Durability: Performs reliably under extreme engine bay temperatures.

-

Chemical Resistance: Maintains its properties despite exposure to engine fluids, grease, or road debris.

These features contribute to the mount’s ability to preserve vehicle comfort and drivetrain health over extended service life.

Common Signs of Failure

Over time, the front insulator mount can wear out due to mechanical stress, exposure to heat and fluids, or natural rubber aging. Recognizing early signs of failure can help prevent secondary damage to the engine and drivetrain components.

Typical symptoms of a worn or damaged front engine mount include:

-

Increased Cabin Vibration

A failed mount no longer isolates engine movement effectively, leading to noticeable vibrations inside the cabin, particularly at idle. -

Engine Movement or Rocking

The engine may shift or rock noticeably under load, gear engagement, or when the vehicle is started or shut off. -

Knocking or Clunking Sounds

Loose or degraded mounts may cause metallic impact noises during sudden acceleration, deceleration, or when driving over bumps. -

Visual Deterioration

Cracked, torn, or collapsed rubber insulators indicate the need for immediate replacement. -

Leaking Fluid (in hydraulic types)

In mounts with hydraulic chambers, fluid leaks are a clear sign of internal failure. -

Misalignment of Connected Components

When engine alignment is affected, it can cause issues with belts, hoses, exhaust pipes, or cooling systems.

Installation Guidelines

Proper installation is essential to ensure that the front insulator engine mount performs effectively and maintains engine alignment.

Basic steps in installation include:

-

Prepare the Vehicle

Park on a level surface, engage the handbrake, and disconnect the battery. -

Support the Engine

Use a jack with a block of wood under the oil pan or an overhead engine support bar to prevent the engine from dropping when the mount is removed. -

Access the Mount

Remove any components obstructing the mount, such as engine covers, air filter housings, or cross braces. -

Unbolt the Old Mount

Carefully unfasten bolts securing the mount to the chassis and engine block. Remove the mount. -

Install the New Mount

Position the new insulator, ensuring it aligns with all bolt holes. Insert and tighten bolts to manufacturer torque specifications. -

Reassemble and Test

Reinstall removed components, start the engine, and observe for any unusual movement or sounds.

Maintenance and Inspection

Although the mount itself does not require routine servicing, regular visual inspection during engine service is recommended.

Inspection checklist includes:

-

Check for cracked, hardened, or oil-soaked rubber

-

Look for engine misalignment or tilting

-

Listen for clunks or rattles when driving or changing gears

-

Inspect for signs of metal-on-metal contact near the mount

Early detection of deterioration helps prevent more severe mechanical issues.

Benefits of Replacing a Worn Front Engine Mount

-

Improved Ride Comfort: Reduces engine vibrations and noise inside the cabin.

-

Restored Engine Stability: Maintains proper engine positioning and alignment with the transmission and chassis.

-

Extended Component Life: Prevents excess movement that can damage belts, hoses, and drivetrain parts.

-

Enhanced Driving Performance: Ensures smoother gear changes, better throttle response, and quieter operation.

-

Lower Long-Term Costs: Prevents collateral damage and reduces the risk of expensive repairs.

Follow us on Facebook for more parts.

Reviews

Clear filtersThere are no reviews yet.