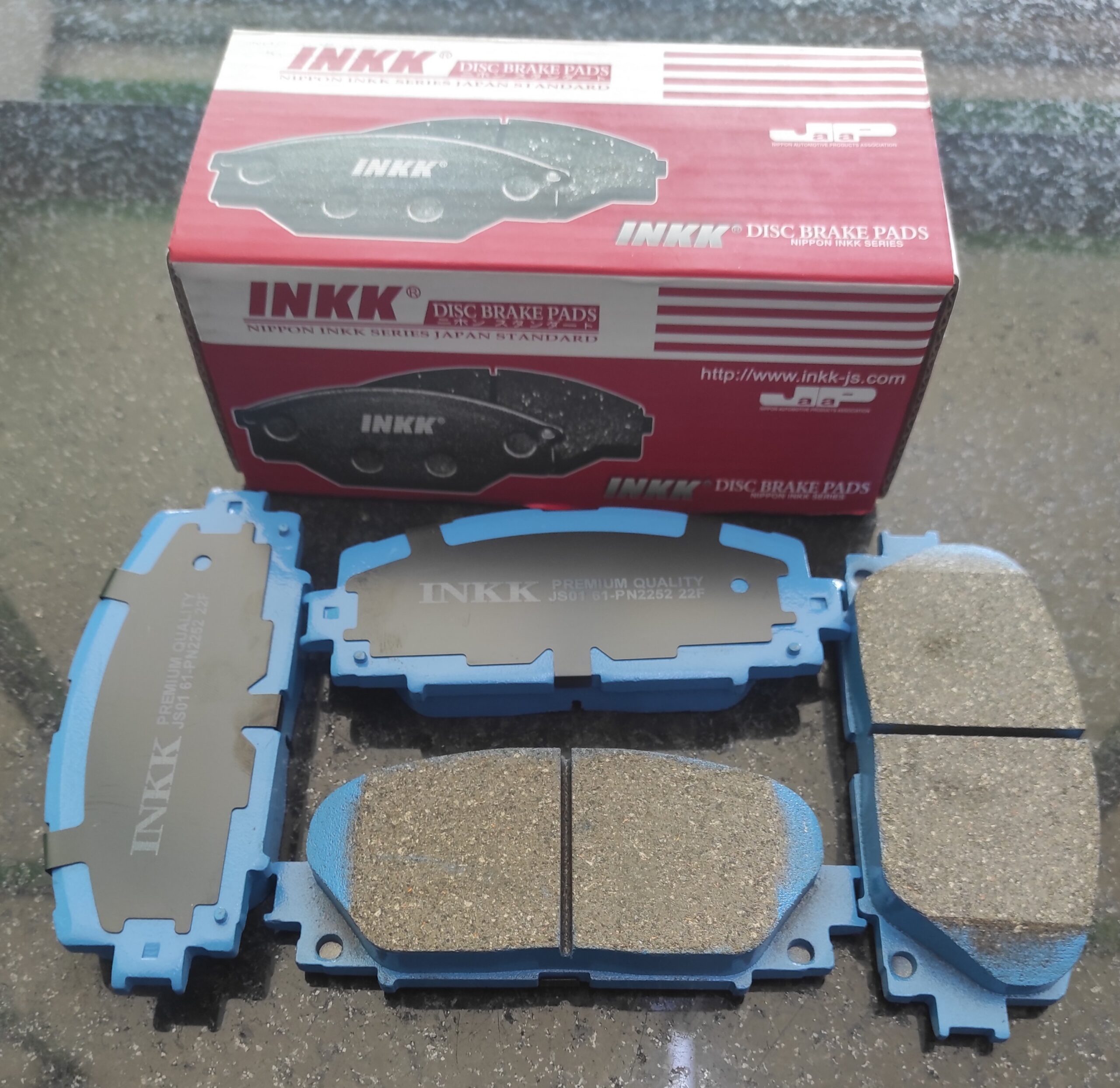

Get Toyota Belta Front Brake Pad Kit D2252 in Kenya

The Front Brake Pad Kit is an essential component of a vehicle’s braking system, designed to ensure effective deceleration and reliable stopping power. Located within the front brake calipers, the brake pads are the primary contact surface that press against the brake rotors (discs) to create the friction needed to slow down or stop the vehicle. Supplied as a set for both front wheels, the kit typically includes multiple brake pads—usually four, two for each wheel—and may also come with shims, clips, or anti-squeal accessories depending on the design.

In most vehicles, the front brakes handle a greater share of the braking load—typically around 60–70%—which makes the front brake pad kit one of the most critical safety components in any car, SUV, or light truck.

Primary Function of Front Brake Pads

The function of front brake pads is to convert kinetic energy into thermal energy through friction. When the driver presses the brake pedal, hydraulic pressure from the master cylinder causes the calipers to clamp the pads onto the spinning rotors. This contact slows the rotation of the wheels, thereby slowing or stopping the vehicle. The effectiveness, heat resistance, and durability of the pads determine how smoothly and safely the vehicle can stop under different driving conditions.

Components of a Standard Front Brake Pad Kit

-

Brake Pads (x4)

Each kit includes two inner and two outer pads, one set per wheel. These pads consist of:-

Friction Material (the part that contacts the rotor)

-

Steel Backing Plate (provides structure and transfers force from the caliper)

-

Adhesives or Rivets to bond the friction material to the backing plate

-

-

Shim or Noise-Dampening Plates (optional)

These thin metal or composite layers are affixed to the back of the pads to reduce vibration and brake noise. -

Abutment Clips or Anti-Rattle Clips

Help secure the pads within the caliper bracket and reduce movement that may cause squeaking. -

Wear Indicators (optional)

Some pads include mechanical or electronic sensors to alert the driver when the pad material is worn and needs replacement. -

Grease Packet (optional)

High-temperature brake grease is included in some kits for lubricating contact points to reduce squeal and ease installation.

Materials Used in Brake Pads

The performance and durability of brake pads heavily depend on the materials used in their construction. Common types include:

-

Semi-Metallic Pads

Made with a mixture of metals (iron, copper, steel) and friction modifiers. These are known for durability and heat dissipation, making them suitable for high-performance or heavy-duty applications. -

Ceramic Pads

Composed of ceramic fibers and nonferrous filler materials. They offer quieter operation, produce less brake dust, and have a longer lifespan. Ideal for everyday driving with low-to-moderate braking demands. -

Organic (Non-Asbestos Organic or NAO) Pads

Made from natural fibers like rubber, glass, and Kevlar. They are soft, quiet, and gentle on rotors, but wear faster and may not perform well under high heat or aggressive braking.

How Front Brake Pads Work

When the brake pedal is pressed, a sequence of hydraulic actions is initiated:

-

Brake Booster Assistance

In most vehicles, a brake booster multiplies the force applied to the pedal. -

Hydraulic Pressure Transmission

The brake master cylinder sends pressurized brake fluid to the front calipers. -

Caliper Movement

The caliper piston(s) are pushed outward, forcing the inner pad against the rotor. This reaction pulls or slides the outer pad into contact as well. -

Friction and Heat Generation

The friction between the pads and the rotating disc slows down the wheel. Energy is converted to heat, which is dissipated through the rotor and airflow.

This process happens instantly and repeatedly with every application of the brake pedal.

Signs of Worn or Failing Front Brake Pads

Front brake pads wear out over time and must be inspected and replaced regularly. Common symptoms of worn or failing pads include:

-

Squealing or Screeching Noise

Often caused by built-in wear indicators or lack of lubrication. -

Grinding Noise

A sign that the friction material is completely worn down, causing metal-on-metal contact with the rotor. -

Reduced Braking Efficiency

Longer stopping distances, or a “spongy” pedal feel, indicate diminished pad effectiveness. -

Brake Warning Light

In vehicles with electronic sensors, the dashboard may alert you to worn pads. -

Pulling to One Side

Uneven wear on brake pads or sticking calipers may cause the vehicle to veer during braking.

Benefits of Maintaining Your Front Brake Pads

-

Enhanced Safety

Reliable braking response is critical in emergencies and everyday driving. -

Preservation of Brake Rotors

Worn pads can damage rotors, leading to more expensive repairs. -

Improved Vehicle Handling

Smooth and consistent braking helps maintain vehicle balance during deceleration. -

Fuel Efficiency and Comfort

Properly functioning brakes reduce drag, improve fuel economy, and provide smoother rides.

Installation and Replacement Tips

Replacing front brake pads is a routine maintenance task. It involves:

-

Lifting and securing the vehicle

-

Removing the front wheels

-

Unbolting the caliper and swinging it aside

-

Removing the old pads and installing new ones

-

Lubricating caliper contact points (if necessary)

-

Reassembling the components and performing a test drive

After replacement, brake pad bedding may be required. This involves a series of moderate stops to evenly transfer a layer of friction material onto the rotors, improving performance and longevity.

When to Replace Front Brake Pads

The lifespan of front brake pads varies depending on the material, driving habits, and terrain. However, most pads last between 30,000 to 70,000 kilometers. Regular inspections—preferably every 10,000 km—are recommended. Pads should be replaced when:

-

Friction material is less than 3mm thick

-

Brake performance declines

-

Squealing or grinding noises persist

-

Visual indicators show significant wear

Environmental and Safety Standards

Modern brake pads are increasingly manufactured with eco-friendly materials. Regulations in many countries have phased out the use of asbestos and restricted the use of heavy metals like copper. High-quality brake pads now meet or exceed ECE R90, ISO, or OEM specifications, ensuring safety and performance standards are maintained globally.

Follow us on Facebook for more parts.