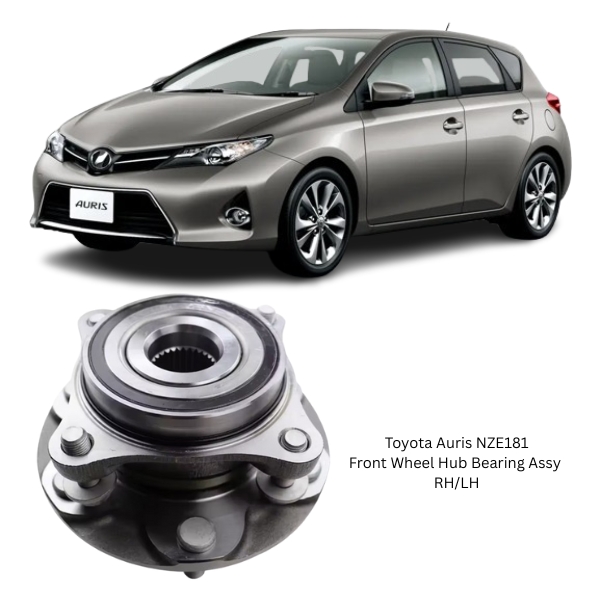

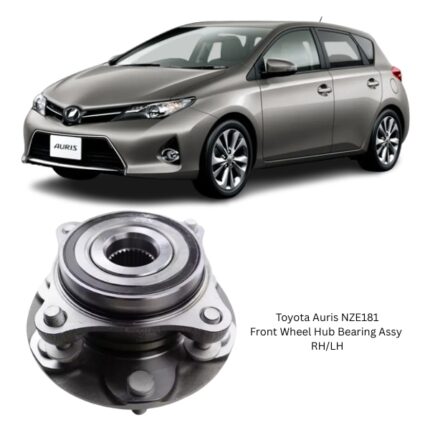

Get Toyota Auris NZE181 Front Wheel Hub Bearing Assy RH/LH 43550-42010 in Kenya

The Front Wheel Hub Bearing Assembly RH/LH is a critical component in the architecture of modern front suspension systems. Serving as the main interface between the wheel and the suspension, this assembly supports vehicle weight, facilitates smooth wheel rotation, and ensures accurate alignment for braking, steering, and stability. The unit is symmetrically engineered to fit both right-hand (RH) and left-hand (LH) positions on the front axle, integrating key mechanical elements into a compact and durable design.

Functional Overview

The core function of the Front Wheel Hub Bearing Assembly is to enable the wheel to rotate smoothly while enduring the intense physical loads generated during driving. These loads include vertical forces from the vehicle’s weight, lateral forces during cornering, and torsional stresses during acceleration and braking. Additionally, the assembly provides a solid mounting base for the wheel and brake disc or drum and often integrates a sensor mechanism for vehicle stability and braking systems.

This multifaceted functionality positions the hub bearing assembly as a structural and dynamic linchpin within the broader mechanical system.

Construction and Subcomponents

The assembly is typically manufactured as a sealed unit that combines several precision-engineered subcomponents:

1. Hub Flange

The hub flange is a disc-shaped structure that connects directly to the vehicle’s wheel. It contains studs or threaded holes for bolting the wheel in place and often includes additional surfaces for the brake rotor. This flange is designed to transmit the vehicle’s load and driving torque evenly across the wheel’s surface.

2. Bearing Assembly

The core of the unit is the bearing, typically a double-row ball or tapered roller bearing. These bearings are engineered to handle both radial and axial loads, ensuring smooth rotational performance under varying conditions. The internal surfaces are hardened, precision-ground, and lubricated with high-performance grease.

3. Mounting Flange/Knuckle Interface

On the opposite side of the hub flange, the mounting face interfaces with the steering knuckle or suspension upright. This part of the assembly is usually bolted directly into the suspension structure, ensuring a secure connection that preserves alignment and performance integrity.

4. Seals

The bearing assembly includes multiple seals, typically constructed of rubber or polymer, to prevent ingress of contaminants like dust, water, and road salt. These seals also help retain lubricant within the bearing chamber.

5. Sensor Compatibility (Optional)

Many hub assemblies integrate a tone ring or magnetic encoder ring that communicates with wheel speed sensors for ABS and traction control systems. These built-in components help transmit precise rotational data, enhancing braking and vehicle stability control functions.

Material Selection and Engineering Precision

The Front Wheel Hub Bearing Assembly is subjected to extreme loads and must be built to stringent durability standards. Materials are chosen not only for strength but also for fatigue resistance, temperature tolerance, and resistance to corrosion.

-

Bearing Components: Usually made from high-carbon chrome steel, the bearing races and rolling elements are heat-treated and polished for fatigue resistance and low rolling friction.

-

Hub Flange and Housing: Typically constructed from forged or cast steel or iron alloys to ensure high tensile strength and dimensional stability.

-

Seals: Composed of synthetic elastomers that resist wear, oil breakdown, and environmental contaminants.

Precision machining ensures the concentricity, preload, and balance required for quiet operation and long service life.

Load Management and Operational Dynamics

The Front Wheel Hub Bearing Assembly must handle several types of mechanical stresses simultaneously:

-

Radial Loads: Vertical forces from the vehicle’s weight and road irregularities.

-

Axial Loads: Lateral forces during turning or lane changes.

-

Torsional Loads: Resulting from acceleration, deceleration, and braking torque.

-

Dynamic Impacts: Such as potholes or curb strikes that introduce shock loads.

High load-bearing capacity and optimized internal geometry allow the unit to perform reliably across these stressors without deforming or developing excess play.

Mechanical Integration

The Front Wheel Hub Bearing Assembly acts as a structural integration point between several vehicle systems:

-

Suspension System: It connects the wheel to the suspension, transmitting load while allowing motion.

-

Steering System: In vehicles with independent front suspension, it is often mounted on a steerable knuckle and must permit rotation without hindrance.

-

Braking System: Brake rotors are typically mounted to the hub, making concentricity and runout tolerance critical to braking performance.

-

Electronic Systems: ABS and traction control sensors often interface directly with the assembly’s tone ring or encoder surface.

Because it integrates such systems, precision and compatibility of the hub assembly are crucial to ensure the proper function of multiple interrelated components.

Failure Modes and Wear Indicators

Though robust, the hub bearing assembly is a wear item and may eventually degrade under normal use. Common failure indicators include:

-

Growling or grinding noises during wheel rotation, especially at speed.

-

Vibration or feedback in the steering wheel, particularly when turning.

-

Uneven or rapid tire wear due to misalignment or play.

-

ABS light activation stemming from sensor errors or tone ring damage.

-

Wheel wobble or looseness, indicating internal bearing failure.

Failure to address these symptoms can lead to compromised handling, reduced braking efficiency, or even wheel detachment in extreme cases.

Installation Considerations

Proper installation of the Front Wheel Hub Bearing Assembly is essential to ensure optimal performance and safety:

-

Torque Specifications: The axle nut and mounting bolts must be tightened to precise values to maintain proper bearing preload.

-

Surface Preparation: Clean mating surfaces are critical to prevent misalignment or improper seating.

-

Sensor Orientation: For units with integrated ABS rings, correct alignment with the speed sensor is essential.

-

Tooling: Specialized tools such as a press or torque wrench may be required for safe and accurate installation.

Incorrect installation can lead to premature failure, increased friction, or degraded performance.

Maintenance and Durability

Most modern Front Wheel Hub Bearing Assemblies are sealed for life and require no routine maintenance. However, their longevity can be maximized through:

-

Avoidance of excessive moisture or road salt exposure.

-

Timely inspection during brake or tire changes.

-

Proper wheel torqueing to avoid bearing distortion.

-

Monitoring vehicle behavior for early signs of wear.

Typical service life can range from 100,000 to 150,000 kilometers under normal driving conditions, though this varies with use and environment.

System Role and Performance Impact

Functioning as both a structural support and a rotating element, the Front Wheel Hub Bearing Assembly is vital to several performance characteristics:

-

Ride Comfort: Ensures minimal vibration and noise.

-

Handling Precision: Maintains alignment and smooth steering response.

-

Braking Efficiency: Facilitates accurate rotor-to-pad contact and sensor feedback.

-

Safety Systems: Provides data and stability input for ABS and traction control.

Compromised performance in this component can ripple through all related systems, making its integrity essential to vehicle safety and dynamics.

Follow us on Facebook for more parts.

Reviews

Clear filtersThere are no reviews yet.