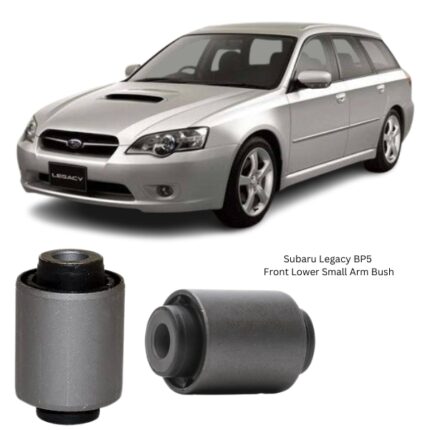

Get Subaru Legacy BP5 Front Lower Small Arm Bush 20204-AG040 in Kenya

The Front Lower Small Arm Bush is a key suspension component used in modern vehicle systems to support the pivot action of the lower suspension arm while reducing vibrations, noise, and harshness during vehicle operation. Although it’s compact in size, it plays a critical role in maintaining suspension geometry, ensuring smooth wheel articulation, and contributing to overall driving stability.

Mounted on the front lower small control arm—commonly used in independent suspension setups—the bushing serves as a flexible coupling between the arm and the vehicle’s chassis or subframe. Its ability to absorb dynamic road loads, manage wheel movement, and isolate the vehicle body from harsh road conditions makes it a cornerstone of suspension performance.

Function and Purpose

The Front Lower Small Arm Bush operates as a pivot point, enabling the front lower control arm to move up and down with the suspension while maintaining lateral and fore-aft stability. It allows controlled motion while resisting unwanted deflection that could affect handling or wheel alignment.

Core Functions:

-

Suspension Articulation

Facilitates smooth up-and-down movement of the lower control arm as the wheels respond to road conditions. -

Vibration Dampening

Absorbs and filters vibrations and minor shocks from the road, reducing their transmission to the vehicle chassis and cabin. -

Alignment Preservation

Helps maintain proper wheel camber and toe angles, which are critical to predictable handling and even tire wear. -

Noise Reduction

Prevents direct contact between metal components within the suspension, eliminating clunks and rattles. -

Load Distribution

Helps distribute braking, acceleration, and cornering forces across the suspension system, reducing stress on surrounding parts.

The performance of the front lower small arm bush is particularly important in vehicles that rely on precise handling and refined ride comfort.

Design and Construction

The Front Lower Small Arm Bush is engineered with both resilience and flexibility in mind, combining robust metal hardware with high-grade elastomeric materials that flex under pressure and return to shape repeatedly without damage.

Key Components:

-

Outer Shell

A cylindrical sleeve made of steel or aluminum, this forms the external structure and is pressed into the housing of the control arm. -

Inner Sleeve

A smaller metal tube through which the suspension bolt passes. It acts as the fixed pivot for the control arm’s movement. -

Rubber or Polyurethane Core

The central elastic portion bonded between the outer and inner sleeves. It allows for controlled flexing, absorbing road forces while ensuring reliable damping. -

Void Geometry (Optional)

Some versions feature engineered voids, cut-outs, or directional grooves in the elastomer to control stiffness in specific directions—optimizing ride quality and performance. -

Adhesive or Mechanical Bonding

A strong chemical bond or interference fit ensures that the elastomer doesn’t separate from the metal sleeves, even under extreme conditions.

These materials are designed to withstand road stress, heat, oil, water, and other contaminants while preserving structural integrity over time.

Performance Features

An effective Front Lower Small Arm Bush offers the following performance benefits:

-

Durability

Built to handle constant flexing, temperature changes, and exposure to road debris without tearing or cracking. -

Precision Fit

Engineered to match original dimensions for secure installation and consistent alignment. -

Fatigue Resistance

Maintains performance across thousands of suspension cycles, even under demanding driving conditions. -

Low NVH Transmission

Minimizes noise, vibration, and harshness (NVH), contributing to a refined driving experience. -

Weather & Corrosion Resistance

Coated or treated materials resist rust and environmental degradation, even in high-moisture or off-road conditions.

Signs of Wear and Failure

Over time, the Front Lower Small Arm Bush can degrade due to mechanical wear, environmental exposure, or age-related hardening of the rubber. Worn bushings reduce suspension control and increase wear on related parts.

Common Symptoms of a Failing Front Lower Small Arm Bush:

-

Clunking or Popping Noises

Often heard during braking, turning, or when driving over rough surfaces. -

Uneven Tire Wear

Misalignment caused by loose bushings may result in abnormal wear patterns on the front tires. -

Steering Instability

Wandering or vague steering feedback can result from control arm movement allowed by worn bushings. -

Poor Ride Comfort

Increased vibration or harshness felt through the steering column or vehicle body. -

Excessive Play in Suspension

Movement in the control arm mount, visible during a physical inspection or when jacked up. -

Rubber Cracking or Separation

Visual signs such as cracked, torn, or missing rubber around the bushing area.

Driving with worn bushings can compromise safety, tire life, and handling performance.

Installation Guidelines

Replacing the Front Lower Small Arm Bush typically involves removing the control arm and pressing out the old bush. Depending on vehicle design, it may require specialized tools and mechanical expertise.

General Installation Steps:

-

Vehicle Lift

Secure the vehicle on a lift or jack stands. Remove the front wheel for better access. -

Control Arm Removal

Unbolt the lower arm from the subframe and ball joint assembly. Remove it carefully to avoid damaging adjacent components. -

Old Bushing Extraction

Use a hydraulic press or bushing removal tool to press out the old bush. -

New Bushing Installation

Align and press in the new bushing, ensuring it is fully seated and properly oriented. -

Reinstallation

Bolt the control arm back into place, torquing all bolts to manufacturer specifications. -

Wheel Alignment

It is highly recommended to perform a wheel alignment after installation to restore proper suspension geometry.

Maintenance and Inspection

While bushings don’t require lubrication or routine maintenance, they should be visually inspected during:

-

Suspension service or repairs

-

Shock or coil spring replacements

-

Brake servicing

-

After hitting potholes or rough terrain

Inspecting bushings regularly—especially in high-mileage or off-road vehicles—can help prevent costly suspension damage.

Advantages of Timely Replacement

-

Restored Handling Precision

Ensures accurate steering and improved vehicle response. -

Reduced Noise and Vibration

Keeps the cabin quiet and free from annoying clunks or vibrations. -

Increased Tire Life

Maintains correct alignment, preventing premature wear on tire edges. -

Extended Suspension Longevity

Reduces mechanical stress on adjacent components like struts, ball joints, and tie rods. -

Improved Braking Stability

Prevents unwanted shifting of the suspension during sudden braking.

Follow us on Facebook for more parts.

Reviews

Clear filtersThere are no reviews yet.