-20%

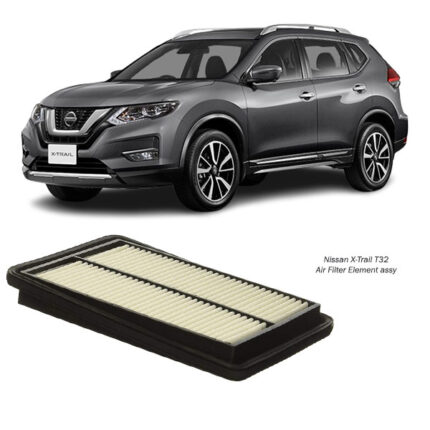

Get Nissan X-Trail T32 Air Filter Element Assy 16546-4BA1A in Kenya

An Air Filter Element Assembly (Assy) is a crucial component used in various applications, primarily in automobiles 🚗, industrial machinery 🏭, and HVAC systems 🌬️. It ensures that the air entering the engine or ventilation system is free from dust, debris, and contaminants. Without a properly functioning air filter, engines and machines would suffer from reduced efficiency, increased wear and tear, and higher maintenance costs.

This guide covers everything you need to know about air filter element assemblies, including their function, types, materials, maintenance, and benefits.

1️⃣ Function of an Air Filter Element Assembly

The air filter element assembly is designed to:

✔️ Prevent Contaminants 🦠: It traps dust, dirt, pollen, and other airborne particles, ensuring clean air intake.

✔️ Improve Performance 🚀: Clean air improves combustion efficiency in engines, leading to better fuel economy and power output.

✔️ Extend Engine Life 🔧: It prevents contaminants from reaching sensitive engine components, reducing wear and tear.

✔️ Enhance Air Quality 🌱: In HVAC systems, air filters help improve indoor air quality by removing allergens and pollutants.

Without an air filter, an engine or ventilation system would be exposed to harmful debris, leading to clogging, overheating, and possible damage.

2️⃣ Types of Air Filter Element Assemblies

There are several types of air filters used in different applications:

A. Based on Material

🟡 Paper Filters 📜 – Most common in automotive engines. Made of pleated cellulose material, offering good filtration but requiring frequent replacement.

🟠 Foam Filters 🧽 – Made from polyurethane foam, often used in motorcycles, small engines, and off-road vehicles. They are reusable and can be oiled for better filtration.

🔵 Cotton Gauze Filters 🌿 – High-performance filters (e.g., K&N filters), used in sports cars and racing applications. They are washable and reusable.

🔴 Synthetic Fiber Filters 🧵 – Used in HVAC systems, providing superior filtration efficiency and longer lifespan.

B. Based on Design

📦 Panel Air Filters – Common in cars and HVAC systems. Flat and rectangular with pleated filtration media.

🌀 Conical & Cylindrical Filters – Found in high-performance and industrial applications, offering better airflow and filtration efficiency.

🎛 Canister Filters – Used in heavy-duty engines and industrial applications, featuring a sealed housing to protect against harsh environments.

C. Based on Usage

🚗 Automotive Air Filters – Installed in the air intake system of vehicles to ensure clean air enters the engine.

🏭 Industrial Air Filters – Used in factories and large machinery to prevent dust accumulation in critical components.

🌬 HVAC Air Filters – Used in air conditioning and heating systems to maintain clean indoor air.

Each type has different advantages and applications, depending on the environment, level of filtration needed, and maintenance preferences.

3️⃣ Components of an Air Filter Element Assembly

A standard air filter element assembly consists of:

🟢 Filter Media – The main component that traps contaminants (paper, cotton, foam, or synthetic fibers).

🔵 Frame or Housing – Provides structural support (made of plastic, metal, or rubber).

🟠 Gaskets & Seals – Prevent unfiltered air from bypassing the filter.

⚫ Wire Mesh or Screens – Used in some filters to reinforce the filtration media and improve durability.

The quality and construction of these components determine the filter’s efficiency, durability, and airflow characteristics.

4️⃣ How Air Filter Element Assemblies Work

The working principle of an air filter is simple but highly effective:

1️⃣ Air enters through the intake system or ventilation duct.

2️⃣ Contaminants like dust, pollen, and debris get trapped in the filter media.

3️⃣ Clean air passes through and reaches the engine or indoor environment.

4️⃣ Over time, the filter gets clogged and needs to be cleaned or replaced.

This simple yet essential process ensures optimal engine performance, clean indoor air, and reduced wear on machinery.

5️⃣ Signs of a Dirty or Failing Air Filter 🚨

A clogged or failing air filter can cause various issues. Look out for these signs:

❌ Reduced Engine Performance – Sluggish acceleration and poor fuel economy.

❌ Increased Fuel Consumption ⛽ – A clogged filter makes the engine work harder, consuming more fuel.

❌ Unusual Engine Noises 🚨 – Whistling or coughing sounds may indicate restricted airflow.

❌ Dark Smoke from the Exhaust 🚗💨 – A dirty filter leads to incomplete combustion, causing black smoke.

❌ Strange Smells in HVAC Systems 🌫️ – Musty odors may indicate mold or excessive dust buildup.

Ignoring these signs can lead to engine damage, poor air quality, and costly repairs.

6️⃣ Maintenance & Replacement of Air Filters 🛠️

To keep your air filter in top condition, follow these maintenance tips:

🔹 Regular Inspection – Check the filter every 5,000 to 15,000 miles (varies by vehicle and environment).

🔹 Cleaning – If it’s a reusable filter (foam or cotton gauze), clean it using specialized cleaning kits.

🔹 Replacement – Paper filters must be replaced when dirty. Follow manufacturer recommendations for best performance.

🔹 Check for Damage – Ensure seals and gaskets are intact to prevent unfiltered air from entering.

Proper maintenance improves engine efficiency, reduces emissions, and prolongs component life.

7️⃣ Benefits of Using a High-Quality Air Filter 🌟

Using a premium air filter element assembly offers multiple advantages:

✅ Better Engine Performance – Ensures optimal air-fuel mixture for smooth combustion.

✅ Extended Engine Life – Prevents wear and tear by keeping debris out.

✅ Improved Fuel Efficiency ⛽ – Reduces engine strain, leading to better mileage.

✅ Cleaner Air & Reduced Allergies 🤧 – Essential for HVAC systems to maintain good indoor air quality.

✅ Lower Maintenance Costs 💰 – A good filter reduces the risk of expensive repairs.

Investing in a high-quality filter is a small cost compared to potential engine damage or poor indoor air quality.

Conclusion 🎯

An Air Filter Element Assembly is a vital component in automobiles, industrial machinery, and HVAC systems. It plays a key role in removing contaminants, improving efficiency, and protecting engines and equipment.

By understanding its types, components, working principles, and maintenance, you can ensure optimal performance, longevity, and cost savings.

📌 Key Takeaways:

✔️ Choose the right type of filter for your application.

✔️ Inspect and replace filters regularly to avoid issues.

✔️ A clean filter ensures better performance, fuel efficiency, and air quality.

Follow us on Facebook for more parts.