-9%

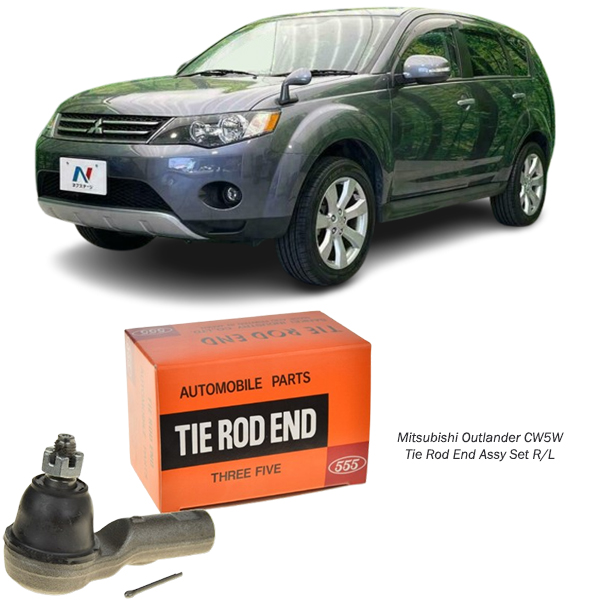

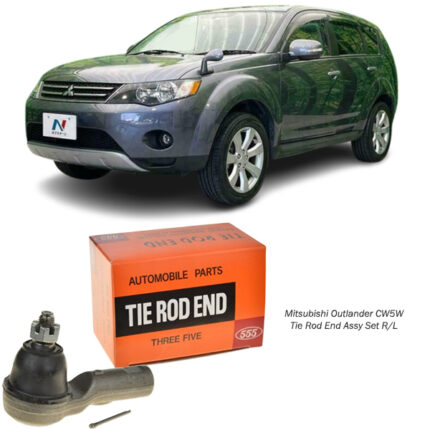

Get Mitsubishi Outlander CW5W Tie Rod End Assy Set R/L SE-B011 in Kenya

The tie rod end assembly set is an essential component of a vehicle’s steering and suspension system. It connects the steering system to the wheels, allowing for precise control over the vehicle’s direction. Properly functioning tie rod ends are crucial for maintaining accurate steering, vehicle alignment, and overall safety on the road. In this comprehensive guide, we’ll explore the functions, components, types, maintenance, signs of wear, and benefits of a well-maintained tie rod end assembly.

1. What is a Tie Rod End Assembly Set?

A tie rod end assembly connects the vehicle’s steering gear or rack to the wheel hub, enabling the wheels to turn left or right in response to the driver’s steering input. It’s made up of an inner and outer tie rod connected by an adjustable sleeve that allows for adjustments in length, ensuring proper alignment of the wheels.

The tie rod assembly essentially transfers force from the steering rack to the wheels, enabling smooth and responsive handling. A standard vehicle may have four tie rod ends, two for each wheel on either side of the car.

2. Function of Tie Rod Ends

Tie rod ends are crucial in ensuring accurate and controlled steering, and they perform the following functions:

a. Transferring Steering Force

The main role of tie rod ends is to transfer the force from the steering rack to the wheel assembly. When you turn the steering wheel, the rack moves the tie rods, which in turn pivot the wheels in the desired direction. This precise force transfer is essential for maintaining directional control and maneuverability.

b. Absorbing Road Impact

Tie rod ends also act as a buffer between the suspension and steering components, helping absorb impacts from road irregularities, such as bumps and potholes. This feature prevents harsh vibrations from transferring to the steering wheel and enhances driving comfort.

c. Maintaining Wheel Alignment

Properly adjusted tie rods help maintain the alignment of the wheels, ensuring they are parallel to each other and at the correct angle relative to the road. This alignment is vital for balanced tire wear, efficient fuel usage, and safe handling.

3. Components of a Tie Rod End Assembly

A tie rod end assembly consists of several parts, each contributing to its overall function:

a. Inner Tie Rod

The inner tie rod is attached to the steering rack. It transfers steering force directly from the steering mechanism to the outer tie rod, moving the wheel assembly.

b. Outer Tie Rod

The outer tie rod connects the inner tie rod to the steering knuckle or spindle of the wheel hub. It pivots to facilitate smooth steering and maintain proper wheel alignment.

c. Tie Rod End Ball Joint

A ball joint is part of the outer tie rod end, allowing it to move in multiple directions to maintain wheel flexibility while providing a stable connection.

d. Adjustable Sleeve

An adjustable sleeve connects the inner and outer tie rods, allowing the length of the tie rod assembly to be adjusted to align the wheels correctly. This sleeve can be rotated to fine-tune the position of the wheels.

4. Types of Tie Rod Ends

Different types of tie rod ends are used based on the vehicle’s design and intended use:

a. Rack-and-Pinion Tie Rods

Rack-and-pinion tie rods are commonly used in modern passenger vehicles. In this setup, the tie rod assembly is connected directly to the steering rack, providing direct and responsive steering control.

b. Parallelogram Steering Tie Rods

This type is used in vehicles with parallelogram steering systems, commonly found in trucks and larger vehicles. The tie rod assembly connects to a central linkage, which translates the steering wheel’s motion to the wheels.

c. Non-Adjustable Tie Rod Ends

Some tie rods come as non-adjustable units, typically pre-set to a specific length and alignment for easy replacement. These are used primarily in vehicles where precise factory settings are critical.

d. Adjustable Tie Rod Ends

Adjustable tie rods allow for wheel alignment adjustments, often found in performance or modified vehicles where precise handling is desired. The adjustability can help maintain alignment, especially after modifications.

5. Maintenance and Replacement of Tie Rod Ends

a. Inspection and Lubrication

Regular inspection of tie rod ends is essential, as they experience significant wear over time. Signs of deterioration, such as cracked rubber, loose fittings, or rust, indicate that the tie rod may need lubrication or replacement. Periodic lubrication of the ball joint can also help extend the life of the tie rod, especially in older models or heavy-use vehicles.

b. Replacing Worn Tie Rod Ends

Tie rod end replacement should be carried out by a professional, as it requires specific tools and expertise to ensure proper alignment. The basic steps for replacement include:

- Elevating the Vehicle: Use a jack and stands to lift the vehicle and give access to the tie rod ends.

- Removing the Old Tie Rod End: The cotter pin and retaining nut are removed, and a puller is used to detach the old tie rod end from the steering knuckle.

- Installing the New Tie Rod End: The new tie rod end is secured and aligned with the steering knuckle and inner tie rod.

- Alignment Check: After installation, a wheel alignment is necessary to ensure proper handling and even tire wear.

c. Wheel Alignment

Whenever a tie rod end is replaced, a wheel alignment should follow to maintain vehicle stability and prevent uneven tire wear. Misaligned wheels can compromise handling and may lead to poor fuel economy.

6. Signs of Worn Tie Rod Ends

Detecting worn tie rod ends early can prevent further damage to the suspension and steering components. Common symptoms of worn tie rod ends include:

a. Uneven Tire Wear

When tie rods are worn, they can cause uneven or excessive tire wear due to improper alignment. If your tires show signs of unusual wear patterns, it could indicate a problem with the tie rods.

b. Shaking or Vibration in the Steering Wheel

If the steering wheel vibrates, especially at higher speeds or on uneven roads, it may be due to loose or damaged tie rods. This issue affects handling and can make driving uncomfortable.

c. Loose or Unresponsive Steering

Worn tie rod ends can make the steering feel loose or unresponsive. If you notice excessive play or have to turn the steering wheel more than usual, it’s likely due to tie rod wear.

d. Clunking or Knocking Noises

When tie rod ends wear out, they can produce clunking or knocking sounds, especially when going over bumps or making sharp turns. These noises are due to the ball joint losing stability within the socket.

7. Benefits of Healthy Tie Rod Ends

Ensuring that the tie rod ends are in good condition offers several advantages:

- Enhanced Steering Precision: Properly functioning tie rod ends provide better control and a more responsive steering feel.

- Improved Vehicle Stability: Healthy tie rods keep the wheels in proper alignment, maintaining stability and smoothness.

- Even Tire Wear: Balanced tire wear leads to longer tire life and cost savings.

- Better Fuel Economy: Proper wheel alignment contributes to more efficient fuel use.

- Safe Handling: Worn tie rods can compromise handling, making driving safer and more enjoyable.

8. Causes of Tie Rod End Wear

Tie rod ends endure constant stress due to road conditions and steering demands, which can lead to wear over time. Common causes include:

- Environmental Factors: Exposure to moisture, road salt, and extreme temperatures can degrade the rubber and metal parts of the tie rod end, causing rust and wear.

- Rough Driving Conditions: Potholes, speed bumps, and off-road driving put extra strain on tie rod ends, accelerating their wear.

- High Mileage: Frequent and long-distance driving increases the stress on tie rods, eventually leading to fatigue and failure.

Conclusion

The tie rod end assembly set plays an essential role in maintaining steering accuracy, vehicle stability, and safe handling. Regular inspections, timely replacement, and proper wheel alignment are necessary for maintaining the health of these components. By understanding the importance of tie rod ends and identifying signs of wear, drivers can enjoy improved vehicle performance, longer tire life, and safer driving experiences.

Follow us on Facebook for more parts.