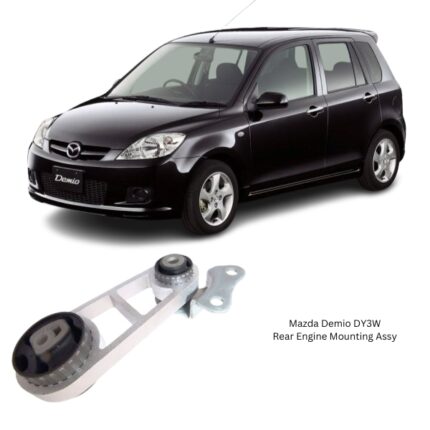

Get Mazda Demio DY3W Rear Engine Mounting Assy D354-39-D40A in Kenya

The Rear Engine Mounting Assembly is a vital structural and functional component of a vehicle’s engine support system. Situated at the rear of the engine or transmission, this mount provides essential stability, vibration control, and torque absorption, working together with other engine mounts to ensure the engine stays securely in place while operating smoothly.

Unlike side engine mounts that control lateral movement, the rear engine mount is specifically tasked with controlling longitudinal movement—that is, back-and-forth engine motion generated during gear shifts, acceleration, and braking. As such, it plays a crucial role in preserving powertrain alignment, reducing Noise, Vibration, and Harshness (NVH) levels, and maintaining the integrity of surrounding components such as exhaust pipes, drive shafts, and electrical harnesses.

Core Functions and Purpose

The rear engine mounting assembly is designed with multiple roles in mind:

-

Engine and Transmission Support: Provides structural support to the rear section of the engine and/or transmission assembly.

-

Vibration Damping: Isolates and reduces engine vibrations before they can be transmitted into the vehicle cabin or frame.

-

Torque Reaction Control: Resists rotational forces created by engine torque, especially during rapid acceleration or deceleration.

-

Motion Restriction: Prevents excessive forward or backward movement of the powertrain under load conditions.

-

Component Protection: Prevents stress-related damage to exhaust systems, cooling lines, hoses, and wiring located around the rear of the engine.

By ensuring that the engine remains properly aligned and stable under a variety of driving conditions, the rear mount contributes significantly to both vehicle performance and driver comfort.

Construction and Materials

The Rear Engine Mounting Assembly is engineered to withstand the intense stresses of engine operation, including exposure to heat, vibration, engine fluids, and dynamic loads. Its construction typically involves a combination of metal brackets, elastomeric isolators, and in some cases, hydraulic chambers.

Key Components:

-

Structural Bracket

Often made of forged steel or cast aluminum, this bracket connects the mount to the engine and/or chassis, forming a rigid foundation. -

Rubber or Polyurethane Insulator

The damping core is made from high-durability rubber or synthetic elastomers, bonded to the bracket to absorb vibrations and isolate movement. -

Inner Sleeve or Bushing

A central metal insert runs through the rubber insulator, allowing for secure bolt connection and uniform load distribution. -

Hydraulic Chamber (in advanced designs)

Some mounts include a fluid-filled section to enhance damping characteristics and reduce engine vibrations at idle or low speeds. -

Protective Coatings or Heat Shields

Depending on engine bay configuration, mounts may feature a corrosion-resistant finish or thermal shields to prevent rubber deterioration from heat sources.

This combination of materials allows the mount to provide long-term performance in harsh underhood environments.

Performance Characteristics

The effectiveness of the rear engine mount can be measured by its ability to maintain performance under continuous stress. A properly functioning mount offers:

-

Stability: Supports the engine’s rear weight while resisting torque-induced movement.

-

Vibration Isolation: Significantly reduces the vibrations reaching the cabin.

-

Torque Resistance: Maintains engine alignment even during aggressive driving or gear shifting.

-

Fatigue Resistance: Withstands the rigors of repeated expansion, compression, and twisting cycles.

-

Chemical and Thermal Durability: Maintains integrity when exposed to oil, grease, heat, and road debris.

Together, these characteristics contribute to a smoother ride and longer lifespan for surrounding vehicle components.

Signs of Wear or Failure

The rear engine mount is subject to wear and fatigue over time, especially in high-mileage vehicles or those frequently driven in demanding conditions. Symptoms of a failing mount include:

-

Excessive Vibration

Increased vibrations in the cabin, particularly noticeable at idle or during acceleration. -

Clunking or Thudding Sounds

Audible knocks or impacts, especially during gear changes, turning, or sudden starts/stops. -

Visible Engine Movement

Excessive rocking or shifting of the engine when revving or during gear engagement. -

Fluid Leakage

In hydraulic mounts, leaking fluid indicates a ruptured internal chamber and loss of damping function. -

Misalignment or Tilt

Sagging engine position or belt/pulley misalignment due to mount compression or failure. -

Cracks or Tears in the Insulator

Visual damage to the rubber portion, such as splitting, drying out, or separation from the metal housing.

Prompt replacement upon observing any of these signs can prevent additional stress on the drivetrain, chassis, and suspension components.

Installation Process Overview

Installing a new rear engine mount involves supporting the engine and carefully replacing the worn or damaged mount without altering alignment. The procedure generally follows these steps:

-

Ensure Safety

Park the vehicle securely, engage the handbrake, and disconnect the battery. -

Support the Engine/Transmission

Use a jack with a wood block or an engine support bar to prevent engine sag when the mount is removed. -

Access the Mount

Remove any shields, covers, or exhaust components that block access to the rear engine mount. -

Unbolt the Old Mount

Remove fasteners connecting the mount to the engine and chassis. Extract the old assembly carefully. -

Inspect the Area

Examine nearby mounts and components for wear or damage. Clean mounting surfaces. -

Install the New Mount

Position the new mount in place and secure it using proper torque specifications. -

Reassemble Components

Refit any removed parts and double-check mount alignment and engine clearance. -

Test Drive

After installation, perform a test drive to verify reduced vibration, proper engine behavior, and the absence of abnormal sounds.

Maintenance and Inspection

Though engine mounts do not require frequent servicing, periodic inspection during scheduled maintenance can help detect early signs of deterioration. This is especially important in high-mileage vehicles or those used under tough operating conditions such as heavy towing or stop-and-go urban traffic.

Inspection checklist:

-

Look for cracks, dry rot, or oil saturation in the rubber.

-

Check for fluid leaks from hydraulic mounts.

-

Test for excessive engine movement during startup/shutdown.

-

Listen for noise during gear shifts or acceleration.

-

Inspect fasteners for rust or looseness.

Benefits of Replacing a Faulty Rear Mount

-

Improved Comfort: Eliminates harsh vibrations and cabin buzz.

-

Enhanced Stability: Restores proper engine alignment and minimizes shifting.

-

Longer Engine and Drivetrain Life: Reduces mechanical stress on components.

-

Reduced Noise: Prevents thudding or clunking sounds during operation.

-

Better Gear Engagement: Ensures smoother transmission shifting and throttle response.

Follow us on Facebook for more parts.

Reviews

Clear filtersThere are no reviews yet.