-11%

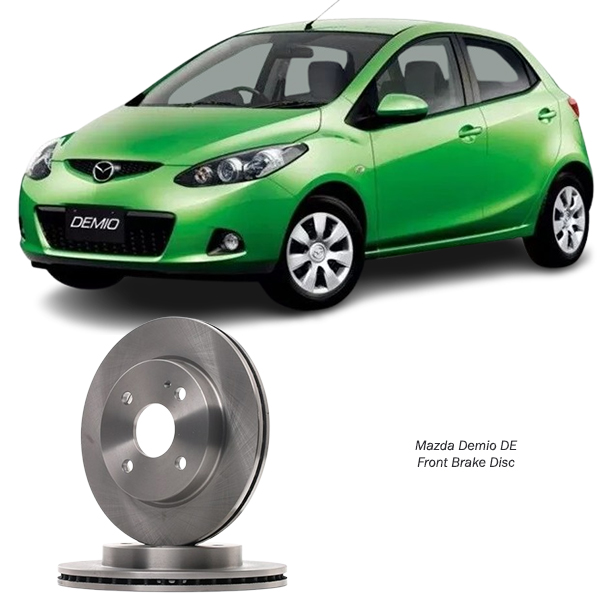

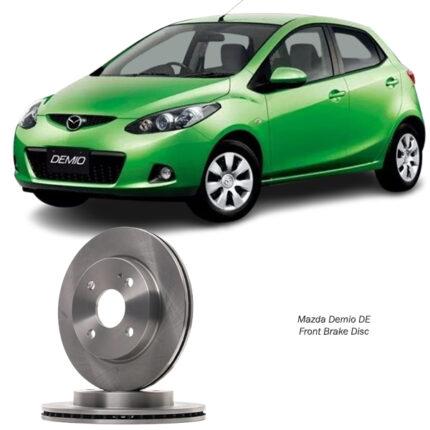

Get Mazda Demio DE Front Brake Disc D651-33-251 in Kenya

The front brake disc, also known as a rotor, is an integral component of a vehicle’s braking system. It works in conjunction with brake pads and calipers to provide the stopping power required for safe driving. Understanding its function, construction, benefits, maintenance, and signs of wear is essential for ensuring optimal performance and safety. This article delves into every aspect of front brake discs in detail.

1. The Function of Front Brake Discs

Front brake discs are responsible for converting the kinetic energy of a moving vehicle into thermal energy through friction, effectively slowing down or stopping the vehicle.

a) Key Roles

- Deceleration: Works with brake pads to slow the rotation of the wheels.

- Heat Dissipation: Designed to withstand and dissipate the heat generated during braking.

- Performance Stability: Maintains consistent braking performance under various conditions.

- Weight Distribution: The front brake discs handle most of the braking force due to weight transfer to the front wheels during braking.

2. Construction of Front Brake Discs

Front brake discs are engineered to endure high stress and temperatures. Their design and material selection play a vital role in performance and durability.

a) Materials

- Cast Iron: The most common material, valued for its durability and heat resistance.

- Carbon-Ceramic: Found in high-performance vehicles, offering superior heat management and reduced weight.

- Steel-Alloy: A blend of steel and other metals, providing strength and corrosion resistance.

b) Design Types

- Solid Discs: Compact and cost-effective, suitable for smaller or less powerful vehicles.

- Ventilated Discs: Features internal vents to improve airflow and heat dissipation.

- Drilled Discs: Contains drilled holes for enhanced cooling and debris removal.

- Slotted Discs: Equipped with grooves for improved braking performance and debris clearing.

3. Benefits of Front Brake Discs

Front brake discs contribute significantly to safety and driving comfort.

a) Safety

- Reliable Stopping Power: Ensures shorter braking distances.

- Heat Management: Prevents brake fade during prolonged or high-intensity braking.

b) Performance

- Consistency: Provides smooth braking under varying road conditions.

- Precision: Delivers immediate response to driver input, especially in emergency situations.

c) Longevity

- Durable Materials: Designed to last tens of thousands of miles with proper care.

- Reduced Wear: Modern designs minimize wear on both the disc and the pads.

4. Maintenance of Front Brake Discs

Regular maintenance of front brake discs is crucial for ensuring their optimal performance and longevity.

a) Inspection

- Visual Check: Look for visible signs of wear, cracks, or uneven surfaces.

- Thickness Measurement: Use a micrometer to ensure the disc thickness meets manufacturer specifications.

- Surface Quality: Check for warping or scoring that may impact braking performance.

b) Cleaning

- Remove Debris: Use a brake cleaner to remove dust and contaminants.

- Avoid Harsh Chemicals: Use products specifically designed for brake components.

c) Replacement

- Timely Changes: Replace the discs when they are below the minimum thickness or show significant wear.

- Matched Replacement: Replace both front discs together to ensure balanced braking.

5. Signs of Worn or Damaged Brake Discs

Early detection of brake disc issues can prevent more severe problems.

a) Common Symptoms

- Vibrations: A warped disc causes vibrations during braking.

- Squealing Noise: Indicates excessive wear or contamination on the disc surface.

- Longer Braking Distance: Reduced braking efficiency due to wear or damage.

- Grooved Surface: Visible scoring or grooves from worn brake pads.

b) Advanced Issues

- Overheating: Bluish discoloration on the disc surface due to excessive heat.

- Cracks: Can form due to repeated heating and cooling cycles.

6. Replacement Process for Front Brake Discs

Replacing front brake discs is a straightforward process but requires precision to ensure safety.

a) Tools Needed

- Jack and Jack Stands

- Wrench Set

- Brake Cleaner

- Torque Wrench

b) Step-by-Step Procedure

- Secure the Vehicle: Park on a flat surface, engage the parking brake, and lift the front end with a jack.

- Remove the Wheel: Loosen the lug nuts and remove the wheel to access the brake assembly.

- Detach the Caliper: Remove the caliper bolts and suspend it with a hanger to avoid damaging the brake line.

- Remove the Old Disc: Unscrew the retaining screws and slide off the old disc.

- Install the New Disc: Clean the hub surface, align the new disc, and secure it with retaining screws.

- Reattach the Caliper: Reposition the caliper and tighten the bolts to the manufacturer’s specifications.

- Replace the Wheel: Reinstall the wheel, lower the vehicle, and tighten the lug nuts.

- Test the Brakes: Pump the brake pedal to restore pressure before driving.

7. Troubleshooting Common Problems

a) Brake Fade

- Cause: Overheating due to excessive or prolonged braking.

- Solution: Allow the brakes to cool and avoid heavy braking where possible.

b) Uneven Wear

- Cause: Faulty calipers or improper installation.

- Solution: Inspect and repair or replace related components.

c) Noise During Braking

- Cause: Worn pads or contaminated disc surface.

- Solution: Replace pads and clean or resurface the discs.

8. Cost and Quality Considerations

a) Factors Affecting Cost

- Material Type: Carbon-ceramic discs are more expensive than cast iron.

- Brand Reputation: High-quality, branded discs often cost more but offer better durability.

- Vehicle Type: Larger or high-performance vehicles require more robust discs.

b) Choosing the Right Disc

- Compatibility: Ensure the disc matches your vehicle’s specifications.

- Driving Style: Opt for performance discs if you drive aggressively or tow heavy loads.

- Environmental Conditions: Use corrosion-resistant discs in regions with high humidity or road salt.

9. Environmental Impact and Recycling

a) Disposal of Old Discs

- Recycling: Cast iron and steel discs are recyclable. Take them to a recycling center or scrap yard.

- Environmental Responsibility: Avoid discarding brake components in landfills to reduce waste.

b) Sustainability Practices

- Material Innovation: Manufacturers are developing eco-friendly materials for brake discs.

- Longevity: High-quality discs reduce the frequency of replacements, lowering overall environmental impact.

10. Conclusion

Front brake discs are vital for ensuring vehicle safety and performance. By understanding their construction, functions, and maintenance needs, vehicle owners can extend the lifespan of their brake system and enhance driving safety. Regular inspections, timely replacements, and choosing high-quality components are essential for keeping your braking system in optimal condition. Investing in the care of your front brake discs not only ensures a smoother and safer driving experience but also reduces long-term repair costs.

Follow us on Facebook for more parts.