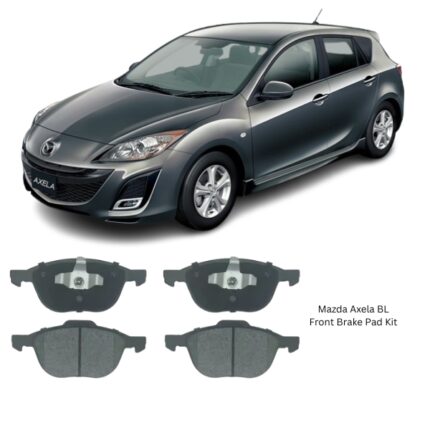

Get Mazda Axela BL Front Ceramic Brake pads D3128 in Kenya

Front ceramic brake pads are a vital component of modern disc brake systems, designed to deliver smooth, quiet, and efficient braking performance while reducing wear and dust. Positioned in the front brake calipers, they provide the friction necessary to slow or stop the vehicle when pressed against the brake rotor.

Unlike traditional organic or semi-metallic brake pads, ceramic brake pads are composed of advanced materials engineered to offer superior braking consistency, low noise, and long-lasting performance. These pads are commonly chosen for daily driving applications where comfort, cleanliness, and reliability are essential.

Construction and Materials

Ceramic brake pads are manufactured using a dense combination of ceramic fibers, bonding agents, and filler materials, which are often reinforced with small amounts of metal fibers such as copper or brass to improve heat conductivity and strength. Key components of a typical front ceramic brake pad include:

-

Friction Material Layer – The main braking surface, composed primarily of ceramic compounds, designed to grip the rotor and dissipate energy through heat.

-

Backing Plate – A steel plate that supports the friction material and allows it to be securely mounted in the caliper.

-

Shim Layer – A noise-reducing barrier, usually made of rubber-coated metal or composite materials, located between the pad and caliper piston to dampen vibration.

-

Chamfers and Slots – Integrated design features that help reduce brake noise, control heat expansion, and manage debris evacuation.

-

Thermal Insulation Layer (in some designs) – Additional protection to minimize heat transfer to the brake caliper and fluid, preserving system integrity under stress.

This advanced composition ensures that ceramic pads offer excellent braking consistency across a wide temperature range, low dust production, and quieter operation compared to other friction materials.

Functional Role in the Braking System

The primary function of front ceramic brake pads is to generate friction when the driver applies the brakes. This friction converts the vehicle’s kinetic energy into thermal energy, allowing the wheels to slow down or stop entirely. In front-wheel braking systems, the front pads bear the majority of the braking load due to weight transfer during deceleration.

Key roles of the front ceramic brake pads include:

-

Providing consistent friction for rapid deceleration and smooth stopping.

-

Resisting brake fade, even during prolonged use or high temperatures.

-

Maintaining rotor integrity by applying uniform pressure with minimal surface damage.

-

Reducing noise and vibration through their dense, stable structure and acoustic shims.

-

Minimizing brake dust buildup on wheels and surrounding components.

Because the front brakes handle most of the stopping force, the quality and integrity of the front ceramic pads are essential to overall vehicle safety and performance.

Advantages of Front Ceramic Brake Pads

When compared to organic or semi-metallic alternatives, ceramic brake pads offer numerous benefits, particularly in urban and highway driving conditions:

-

Quieter Operation – Ceramic materials naturally absorb sound vibrations and are less prone to squealing or grinding.

-

Low Brake Dust – Ceramic pads produce finer dust particles that are lighter in color and less likely to stick to wheels, keeping them cleaner over time.

-

Stable Friction Performance – Maintain consistent braking behavior across a wide temperature range without fading or loss of efficiency.

-

Rotor-Friendly – Less abrasive than semi-metallic pads, reducing rotor wear and extending disc life.

-

Longer Pad Life – Durable construction and wear resistance provide extended service intervals compared to other pad types.

-

Minimal Heat Transfer – Ceramic pads transfer less heat to calipers and brake fluid, preserving the integrity of the entire brake system.

These qualities make ceramic pads an excellent choice for commuters, daily drivers, and light-duty vehicles prioritizing comfort, reliability, and cleanliness.

Typical Applications and Limitations

While ceramic brake pads perform exceptionally well in most driving conditions, there are specific considerations regarding their usage:

-

Ideal For: City driving, highway cruising, family vehicles, and drivers who value low noise and low maintenance.

-

Not Ideal For: Heavy-duty towing, extreme off-roading, or high-performance track use, where more aggressive semi-metallic or carbon-ceramic pads may be preferred due to their higher heat resistance.

It is essential to select brake pads suited to the vehicle’s intended use to ensure optimal performance and safety.

Signs of Wear or Replacement Needs

Over time, even ceramic brake pads wear down and must be inspected or replaced. Common indicators of worn front brake pads include:

-

Squealing or Squeaking – High-pitched noises when braking can signal that the wear indicators are contacting the rotor.

-

Grinding Sounds – A metallic grinding noise indicates the pads have worn through to the backing plate and are contacting the rotor directly.

-

Increased Stopping Distance – A loss in braking responsiveness or longer stopping times may point to reduced friction material.

-

Brake Warning Light – Some vehicles are equipped with sensors that trigger a warning light when pads reach minimum thickness.

-

Visible Wear – Pads that appear to be 3mm thick or less should be replaced.

-

Vibration or Pulling – Uneven wear or warped pads can cause steering wheel vibration or pulling during braking.

Timely replacement ensures consistent braking performance and helps protect rotors from damage.

Installation and Replacement Process

Installing front ceramic brake pads requires attention to detail and proper tools. General steps for installation include:

-

Secure the Vehicle – Lift the front end using jack stands and remove the front wheels.

-

Access Brake Calipers – Unbolt and pivot the caliper to expose the old pads.

-

Remove Old Pads and Hardware – Carefully slide out worn pads and remove any retaining clips or shims.

-

Inspect Components – Check the rotor, caliper, and slide pins for wear, rust, or damage.

-

Install New Pads – Fit the ceramic pads into the caliper bracket and ensure proper seating with new shims or clips if provided.

-

Reassemble and Torque Bolts – Reattach the caliper and torque bolts to manufacturer specifications.

-

Bed-In Process – Perform a break-in procedure by gradually heating the pads through several moderate stops, allowing even material transfer onto the rotor surface.

Professional installation is recommended when unsure of specifications or procedures, especially when working with brake fluid or ABS components.

Maintenance Tips for Longevity

To extend the life of front ceramic brake pads and ensure optimal performance:

-

Inspect Regularly – Check pad thickness, rotor condition, and caliper function during routine maintenance.

-

Avoid Excessive Hard Braking – Especially when pads are new or not yet bedded in.

-

Keep Components Clean – Remove accumulated dust and debris from calipers and backing plates.

-

Replace Pads in Pairs – Always replace both front pads simultaneously to maintain balanced braking.

-

Check Brake Fluid Levels – Low or dirty fluid can affect caliper pressure and braking efficiency.

Proper care ensures that ceramic brake pads deliver consistent, fade-free braking over their service life.

Follow us on Facebook for more parts.

Reviews

Clear filtersThere are no reviews yet.