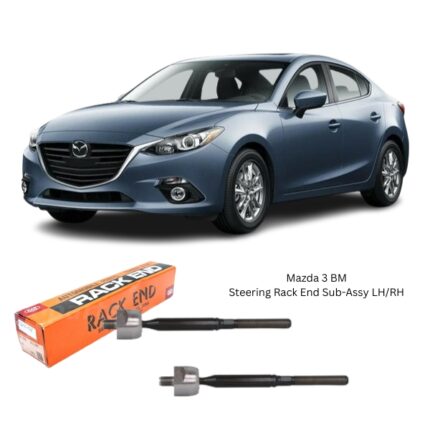

Get Mazda 3 BM Steering Rack End Sub-Assy LH/RH SR-1890 in Kenya

The Steering Rack End Sub-Assembly (LH/RH), also commonly referred to as the inner tie rod, is a critical component of a vehicle’s rack-and-pinion steering system. It connects the steering rack (gearbox) to the outer tie rod, forming a continuous linkage between the steering wheel and the front wheels. The rack end enables the transfer of directional input from the driver to the wheels while also accommodating suspension movement and alignment.

This sub-assembly is responsible for:

-

Delivering smooth and responsive steering input,

-

Maintaining proper toe angle alignment,

-

Ensuring stability under different road and load conditions, and

-

Absorbing road shocks to protect the rest of the steering system.

It is installed in both left-hand (LH) and right-hand (RH) orientations depending on the vehicle’s configuration.

Function and Role in the Steering System

The rack end is the innermost part of the steering linkage. It bolts directly onto or is threaded into the steering rack, extending outward to connect with the outer tie rod end.

Its main functions include:

-

Transmitting lateral steering force from the rack gear to the steering knuckle,

-

Allowing pivoting movement during suspension articulation,

-

Absorbing minor shocks and vibrations to reduce steering wheel kickback,

-

Maintaining the wheel alignment geometry, particularly the toe angle.

During steering, the motion of the rack causes the rack end to push or pull the tie rod, which then rotates the steering knuckle and turns the wheels.

Construction and Design

A typical Steering Rack End Sub-Assy consists of the following parts:

-

Threaded Inner Shaft: This shaft screws directly into the rack or bolts via a socket joint depending on the design. It’s made from heat-treated steel for maximum strength and wear resistance.

-

Ball Joint Housing: At the outer end of the rack end, a ball-and-socket joint allows the part to move in multiple directions, accommodating road movements without compromising steering input.

-

Lock Nut or Washer: Secures the position of the tie rod assembly and allows for alignment adjustments.

-

Dust Boot Seal Groove: A channel or lip on the housing where the steering rack boot is clamped to prevent dust and moisture ingress.

-

Protective Coating: Anti-corrosion treatment is applied to extend the service life in various weather conditions.

-

Socket Grease (Factory-Installed): Reduces friction and ensures smooth motion within the ball joint.

Materials Used

Due to the high-stress conditions under which it operates, the rack end is manufactured from premium-grade materials:

-

Forged or machined carbon steel for the main body,

-

Heat-treated ball studs for hardness and longevity,

-

Polymer liners (in some aftermarket variants) for improved friction control,

-

Zinc or phosphate coating for corrosion protection.

Quality manufacturing ensures long service life and consistent steering feedback even in demanding driving environments.

Types and Compatibility

The Steering Rack End Sub-Assy can vary based on vehicle type and steering design. The most common configurations include:

-

Fixed-length rack ends: Designed to OEM specifications with pre-set dimensions,

-

Adjustable rack ends: Found in some performance vehicles for customizable alignment,

-

LH (Left-Hand) and RH (Right-Hand) sides are typically mirror opposites to match the geometry of the suspension and rack orientation.

They are tailored to match the following vehicle specifics:

-

Steering rack type (manual, electric, or hydraulic),

-

Vehicle suspension system,

-

Front-wheel drive (FWD), rear-wheel drive (RWD), or all-wheel drive (AWD) configuration,

-

Right-hand or left-hand drive setup.

Correct selection of LH/RH versions ensures proper fitment, balanced handling, and reliable steering performance.

Signs of Wear or Failure

As with other steering linkage components, the rack end is subject to wear due to its constant motion, load-bearing function, and exposure to environmental elements.

Common symptoms of a worn or damaged rack end include:

-

Loose or shaky steering, especially at high speeds,

-

Excessive play in the steering wheel,

-

Clunking or knocking sounds when turning,

-

Uneven or rapid tire wear due to toe misalignment,

-

Vehicle pulling to one side during driving,

-

Leaking power steering fluid near the boot or rack housing (in power steering systems),

-

Visible damage or looseness in the inner tie rod during a physical inspection.

Failing to replace a faulty rack end can lead to loss of control, excessive tire damage, and accelerated wear on other suspension components.

Installation Guidelines

Replacing the Steering Rack End Sub-Assy is a moderate-level repair usually performed during suspension or steering maintenance, or when wheel alignment issues are discovered.

Basic installation steps:

-

Raise the vehicle and remove the affected front wheel.

-

Detach the outer tie rod from the steering knuckle and unthread it from the rack end.

-

Remove the steering rack boot to access the inner tie rod.

-

Unscrew the old rack end from the steering rack.

-

Install the new rack end, using thread locker or manufacturer-recommended compound.

-

Reinstall the boot, outer tie rod, and locking nut.

-

Torque all components to OEM specifications.

-

Perform a full wheel alignment to reset the steering geometry.

Many rack ends are supplied with a locking washer, grease packet, or pre-installed ball socket to simplify the replacement process.

Maintenance Tips and Lifespan

Most modern rack ends are sealed for life and require no lubrication. However, inspecting the steering rack boot for cracks or looseness can prevent premature failure.

To extend the life of your rack end:

-

Avoid aggressive driving over potholes or rough terrain,

-

Replace torn boots immediately to prevent contamination,

-

Include steering linkage checks in your routine vehicle inspections.

Under normal conditions, rack ends last 100,000 km to 160,000 km, but this varies with road conditions and vehicle load.

Why Quality Matters

Investing in a high-quality Steering Rack End Sub-Assembly ensures:

-

Consistent steering response across various road conditions,

-

Minimized alignment drift and tire wear,

-

Enhanced vehicle safety,

-

Resistance to corrosion, cracking, or deformation,

-

Perfect fitment for OEM-level performance.

Follow us on Facebook for more parts.

Reviews

Clear filtersThere are no reviews yet.