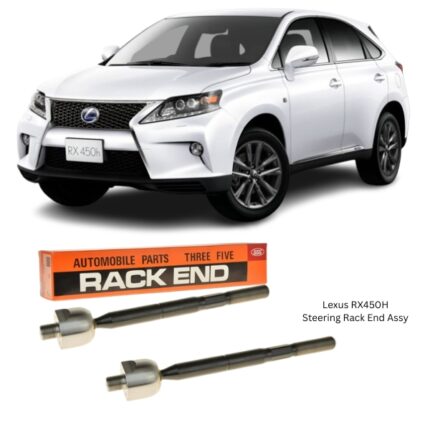

Get Lexus RX450H Steering Rack End Assy SR-T390 in Kenya

The Steering Rack End Assembly is a crucial component in a vehicle’s steering system, connecting the inner workings of the steering rack to the outer tie rod and ultimately to the wheel hub assembly. Often referred to as an “inner tie rod,” this part plays a pivotal role in translating the driver’s input from the steering wheel into precise directional movement of the front wheels. The rack end allows for controlled lateral wheel motion while accommodating the up-and-down movement of the suspension.

When properly functioning, the steering rack end ensures smooth handling, accurate alignment, and consistent road feedback. A worn or faulty rack end can cause erratic steering behavior, reduce handling performance, and compromise overall vehicle safety. That’s why choosing a high-quality Steering Rack End Assembly is essential for any suspension or steering system overhaul.

Key Features

1. High-Tensile Steel Construction

The rack end body and shaft are typically manufactured from forged or heat-treated steel, providing exceptional strength and rigidity. This construction allows the assembly to endure high torque forces and repeated steering motion without bending or premature fatigue.

2. Precision-Machined Threads and Ball Joint

The threaded section of the rack end is engineered to exact dimensions, ensuring a tight and secure connection to both the steering rack and outer tie rod. A ball-and-socket joint at the end provides the flexibility needed for responsive steering, while maintaining structural integrity under varying loads.

3. Smooth Ball Stud Movement

At the joint, a hardened and polished ball stud operates with minimal friction, ensuring smooth pivoting action within the socket. This allows the wheels to move accurately as the steering input is transferred across the steering system.

4. Durable Protective Boot

Most rack ends come with a bellows-style rubber boot that covers the ball joint section to shield it from dirt, debris, water, and other contaminants. This boot preserves the internal grease and prevents premature joint wear, extending the service life of the assembly.

5. Anti-Corrosion Coating

For added durability, the assembly is often coated with anti-corrosion plating—such as black oxide or zinc—to resist rust and environmental degradation. This is especially beneficial for vehicles exposed to moisture, salt, or off-road conditions.

6. OE Fit and Finish

Designed to match original factory specifications, the steering rack end offers a direct fit replacement. This ensures compatibility with existing rack and pinion steering systems and eliminates the need for custom modifications or adjustments during installation.

7. Pre-Lubricated Joint

The inner ball joint is usually pre-lubricated with high-quality grease sealed inside the socket. This eliminates the need for initial servicing and supports smooth steering function from the moment of installation.

8. Complete Kit Option

Some rack end assemblies come as a complete kit, which may include:

-

Steering rack end (inner tie rod)

-

Locking nut

-

Boot (dust cover)

-

Boot clamps

-

Grease packet (for serviceable joints)

-

Installation guide

Performance Benefits

1. Enhanced Steering Accuracy

A high-quality rack end delivers immediate and precise transfer of movement from the steering rack to the wheels, allowing for tighter turning radius, responsive steering, and confident cornering.

2. Improved Suspension Harmony

Since the rack end flexes with the movement of the control arms and suspension, it maintains proper wheel alignment and geometry, which in turn promotes even tire wear and reduces the need for frequent realignment.

3. Reduced Steering Play

Worn or loose rack ends can cause vague or unresponsive steering. A new rack end restores tightness and eliminates free play, resulting in better road feedback and more confident handling.

4. Extended Component Life

By maintaining correct movement and alignment within the steering system, a properly functioning rack end helps reduce stress on the outer tie rod ends, steering knuckles, and wheel bearings.

5. Noise and Vibration Reduction

Replacing a faulty or loose rack end helps eliminate clunking noises and vibrations felt through the steering wheel, particularly during turning or over uneven road surfaces.

Common Signs of a Faulty Steering Rack End

-

Loose or Wandering Steering: Steering that feels vague or unstable, especially at higher speeds.

-

Uneven Tire Wear: Inner or outer edges of the front tires wearing prematurely.

-

Clunking Noise: A knocking sound from the front suspension when turning or braking.

-

Vibration or Shimmy: Excessive steering wheel movement during driving or braking.

-

Steering Wheel Misalignment: The wheel does not return to center smoothly or pulls to one side.

If these symptoms are present, inspection and replacement of the rack end should be prioritized to maintain safe vehicle operation.

Installation Tips

-

Always verify vehicle compatibility before installation.

-

Use the correct tools such as an inner tie rod tool or specialty socket for removal.

-

Ensure the threads are clean and apply thread locker if specified by the manufacturer.

-

Tighten the locking nut to the recommended torque.

-

Replace or inspect the rubber boot for tears or cracks.

-

After installation, always perform a wheel alignment to restore correct toe angle and prevent uneven tire wear.

Maintenance and Care

-

While most modern rack ends are maintenance-free, greaseable options should be serviced during regular vehicle maintenance intervals.

-

Routinely inspect the dust boots for signs of wear, tears, or fluid leakage.

-

Monitor for changes in steering response or noise, as these can indicate early wear.

Why Quality Matters

Choosing a high-quality Steering Rack End Assembly is not just about replacing a worn part—it’s about restoring precision, safety, and comfort to your entire driving experience. Inferior or poorly manufactured rack ends can lead to premature failure, poor handling, or even steering system damage. That’s why it’s critical to use a rack end made from robust materials, tested under real-world conditions, and designed for exact fitment.

Whether you’re performing routine maintenance, restoring steering performance, or replacing worn components after an alignment issue, the steering rack end is a small part that makes a big difference.

Follow us on Facebook for more parts.

Reviews

Clear filtersThere are no reviews yet.