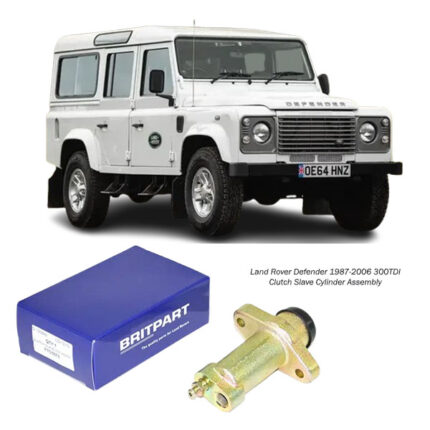

Get Land Rover Defender L316 Clutch Master Cylinder Assembly STC500100 in Kenya

In modern manual transmission vehicles, the Clutch Master Cylinder Assembly is a key component of the hydraulic clutch system. Acting as the primary pump, it converts the mechanical force of pressing the clutch pedal into hydraulic pressure, which in turn activates the clutch slave cylinder to disengage the clutch. Although compact and relatively simple in design, the clutch master cylinder is critical to smooth gear changes, precise clutch engagement, and overall drivability.

If you’re experiencing clutch issues such as a soft pedal, difficulty shifting, or fluid leaks, the clutch master cylinder may be the underlying cause. Understanding its function, components, signs of failure, and benefits is vital for vehicle owners and technicians alike.

What is a Clutch Master Cylinder Assembly?

The Clutch Master Cylinder is a hydraulic device mounted on the firewall of the vehicle, typically above the clutch pedal inside the engine bay. When the driver depresses the clutch pedal, the movement pushes a piston inside the cylinder. This action pressurizes brake fluid (usually DOT3 or DOT4), sending it through a hose or line to the clutch slave cylinder, which then actuates the clutch release mechanism.

In short, it serves as the hydraulic pump that initiates clutch disengagement.

Key Components of the Clutch Master Cylinder Assembly

-

Cylinder Bore

-

A smooth-walled chamber where the piston moves to generate hydraulic pressure.

-

-

Piston

-

Moves forward when the clutch pedal is pressed, forcing fluid into the clutch line.

-

-

Seals and O-rings

-

Prevent internal and external leaks, ensuring pressure is maintained.

-

-

Reservoir

-

Holds brake fluid and supplies it to the cylinder; can be attached directly or connected via a hose.

-

-

Push Rod

-

Links the clutch pedal to the piston inside the master cylinder.

-

-

Return Spring

-

Ensures the piston returns to its original position when the clutch pedal is released.

-

-

Fluid Outlet Port

-

Connects to the clutch hydraulic line that leads to the slave cylinder.

-

How the Clutch Master Cylinder Works

The operation of the clutch master cylinder follows this basic sequence:

-

The driver presses the clutch pedal.

-

The pedal force pushes the push rod, which in turn drives the piston inside the master cylinder.

-

The movement of the piston builds hydraulic pressure in the brake fluid.

-

This pressurized fluid travels through a hydraulic hose or pipe to the slave cylinder.

-

The slave cylinder then actuates the clutch fork or release bearing to disengage the clutch.

-

When the pedal is released, the return spring brings the piston back, and fluid pressure drops, re-engaging the clutch.

Benefits of a High-Quality Clutch Master Cylinder

1. Smooth and Consistent Clutch Engagement

A properly functioning master cylinder allows for consistent fluid pressure, ensuring smooth clutch operation with every pedal press.

2. Reduced Pedal Effort

Quality components provide efficient hydraulic transfer, reducing the force needed to engage the clutch—ideal for long drives or heavy traffic.

3. Enhanced Gear Shifting

With reliable pressure delivery to the slave cylinder, gear changes become more responsive and precise.

4. Longer Clutch Life

Even pressure application reduces clutch wear and prevents harsh engagement or slippage.

5. Leak-Free Performance

High-grade seals and materials resist wear, fluid breakdown, and temperature extremes, offering long service life without maintenance.

Disadvantages of a Faulty Clutch Master Cylinder

A failing clutch master cylinder can introduce a range of drivability and safety issues:

1. Soft or Spongy Pedal

Air in the system or internal leakage can make the pedal feel mushy, unresponsive, or travel too far without disengaging the clutch.

2. Difficulty Engaging Gears

When the master cylinder fails to produce adequate pressure, the clutch may not disengage fully, making it hard to shift—especially into first or reverse.

3. Pedal Stuck to the Floor

A failing return spring or internal seal failure may prevent the pedal from returning to its original position.

4. Fluid Leaks

Brake fluid leaking from the master cylinder or lines can lead to pressure loss, contamination, and eventual clutch system failure.

5. Clutch Slippage

Contaminated fluid or weak pressure can result in partial clutch disengagement, causing the clutch to slip or overheat.

Common Signs of a Worn or Failing Clutch Master Cylinder

-

Spongy or inconsistent clutch pedal feel

-

Fluid leaking on the firewall, under the clutch pedal, or from the reservoir

-

Pedal sinks to the floor and doesn’t return

-

Difficulty or grinding when shifting gears

-

Low or empty fluid reservoir despite no visible leaks (may indicate internal leak)

-

Air bubbles in the fluid during bleeding

Regular inspection during service intervals is advised to detect early signs of failure.

How to Replace a Clutch Master Cylinder

Tools and Materials Needed:

-

Wrenches and socket set

-

Line wrench (for hydraulic fittings)

-

Brake fluid (DOT3 or DOT4, as specified)

-

Bleeder kit

-

Safety gear (gloves, goggles)

-

New clutch master cylinder

Replacement Procedure:

-

Locate the Master Cylinder

-

Mounted on the firewall, near the brake master cylinder. Typically has a reservoir on top or connected by hose.

-

-

Remove Hydraulic Line

-

Use a line wrench to carefully disconnect the hydraulic line going to the slave cylinder.

-

-

Detach from Firewall and Pedal

-

Unbolt the cylinder from the firewall and detach the push rod from the clutch pedal.

-

-

Install the New Cylinder

-

Reverse the removal steps. Bolt in place, reconnect the push rod, and secure the hydraulic line.

-

-

Bleed the Clutch System

-

Remove all air from the system to ensure proper pressure transfer and pedal feel.

-

-

Top Off Fluid and Test

-

Fill the reservoir and test clutch function. Check for leaks, pressure retention, and smooth gear engagement.

-

Tips for Maintenance and Longevity

-

Always use fresh, manufacturer-approved brake fluid.

-

Replace both master and slave cylinders together if one fails—this ensures balanced performance and prevents repeat repairs.

-

Bleed the system carefully to avoid trapped air.

-

Inspect seals, hoses, and fluid levels regularly.

-

Don’t mix fluid types (e.g., DOT3 with DOT5).

Hydraulic vs Cable Clutch Systems

Hydraulic systems (with master and slave cylinders) offer several advantages over cable-actuated clutches:

| Feature | Hydraulic Clutch | Cable Clutch |

|---|---|---|

| Pedal Feel | Smoother, consistent | Heavier, mechanical |

| Maintenance | Fluid changes, bleeding | Cable lubrication, adjustment |

| Durability | Fewer mechanical wear points | Cable can snap or stretch |

| Adjustability | Self-adjusting | Manual adjustment required |

Hydraulic systems are generally preferred for modern vehicles due to their refined operation and lower long-term maintenance.

Follow us on Facebook for more parts.

Reviews

Clear filtersThere are no reviews yet.