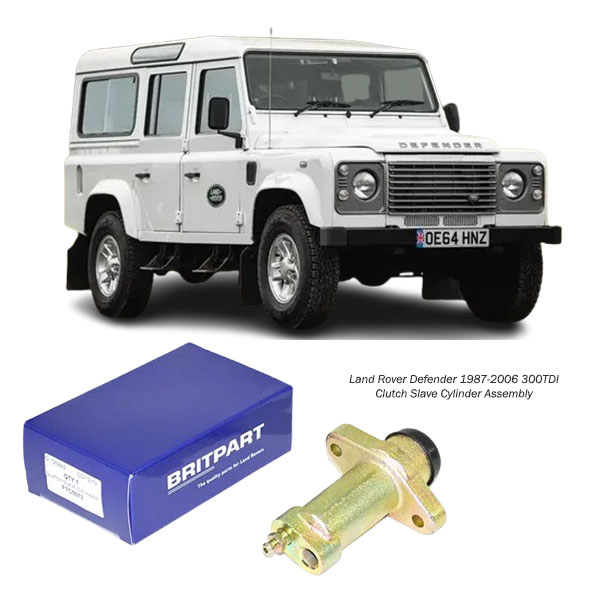

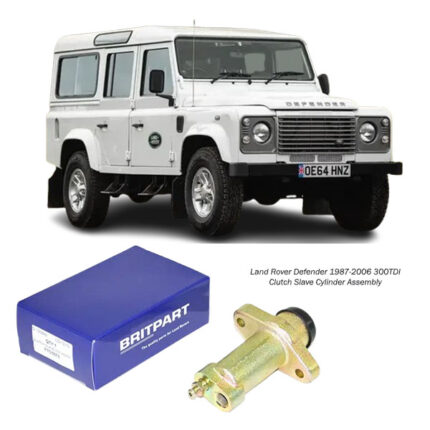

Get Land Rover Defender 1987-2006 300TDI Clutch Slave Cylinder Assembly FTC5072 in Kenya

The Clutch Slave Cylinder Assembly is a crucial component in a vehicle’s hydraulic clutch system. Though often overlooked compared to the clutch disc or pressure plate, the slave cylinder plays a central role in allowing drivers to shift gears effortlessly and consistently. Without it, disengaging the clutch would require immense force or become impossible—especially in modern manual transmission systems.

Whether you are replacing a faulty slave cylinder, troubleshooting gear engagement issues, or learning more about how your vehicle operates, understanding the function, benefits, potential faults, and installation process of the clutch slave cylinder assembly is essential.

What Is a Clutch Slave Cylinder Assembly?

The Clutch Slave Cylinder is a small hydraulic cylinder located near the transmission, responsible for actuating the clutch release mechanism when the driver presses the clutch pedal. It receives pressurized brake fluid from the clutch master cylinder and converts that hydraulic force into mechanical movement.

This action pushes a rod (or piston) that disengages the clutch by pressing against the clutch fork or release bearing, allowing the driver to change gears. When the clutch pedal is released, the hydraulic pressure drops, and the slave cylinder retracts, re-engaging the clutch.

Some modern slave cylinders are integrated into the release bearing assembly, known as a concentric slave cylinder (CSC), which is mounted directly inside the bell housing of the transmission.

Key Components of a Clutch Slave Cylinder Assembly

-

Cylinder Housing: Usually made from cast iron or aluminum, it encases the internal piston and resists hydraulic pressure.

-

Piston & Rod: Moves in response to hydraulic pressure from the master cylinder, pushing the clutch mechanism to disengage the clutch.

-

Seals and O-rings: Ensure the hydraulic fluid stays contained and prevent internal or external leaks.

-

Bleeder Valve: Allows for removal of air from the system during installation or maintenance.

-

Hydraulic Hose Connection: Point where the hydraulic line from the master cylinder connects.

Types of Clutch Slave Cylinders

-

External Slave Cylinder:

-

Mounted outside the transmission bell housing.

-

Pushes on a clutch fork connected to the release bearing.

-

Easier to access and replace.

-

-

Concentric Slave Cylinder (CSC):

-

Combines the release bearing and slave cylinder into one unit.

-

Located inside the transmission, around the input shaft.

-

Offers compact design and more direct movement but is harder to access and replace.

-

How the Clutch Slave Cylinder Works

-

The driver presses the clutch pedal.

-

The master cylinder pressurizes the hydraulic fluid.

-

The pressurized fluid travels through the hydraulic line to the slave cylinder.

-

The slave cylinder piston extends, pushing against the clutch release mechanism.

-

The clutch disengages, allowing gear shifting.

-

When the pedal is released, fluid pressure reduces, and the slave cylinder retracts.

This hydraulic mechanism replaces mechanical linkages and cables, offering smoother, more consistent clutch operation.

Benefits of a High-Quality Clutch Slave Cylinder

1. Smooth Gear Engagement

A properly functioning slave cylinder ensures seamless disengagement of the clutch, allowing precise and jerk-free gear shifts.

2. Light Pedal Effort

Hydraulic clutch systems with high-quality slave cylinders reduce the amount of force required at the pedal, enhancing driving comfort—especially in traffic.

3. Improved Reliability

Well-built slave cylinders with durable seals and materials resist leaks, pressure loss, and internal failure, ensuring consistent performance over time.

4. Noise and Vibration Reduction

A properly functioning slave cylinder prevents excessive wear on the release bearing and clutch fork, minimizing rattling, squeaking, or harsh engagement.

5. Longer Clutch System Lifespan

Stable hydraulic pressure reduces shock loads on the clutch assembly, helping extend the life of the clutch disc, pressure plate, and other components.

Disadvantages of a Faulty Clutch Slave Cylinder

1. Difficulty in Shifting Gears

A failing slave cylinder may not fully disengage the clutch, making it hard to shift—particularly into first gear or reverse.

2. Spongy or Soft Clutch Pedal

If the slave cylinder leaks or has trapped air, the clutch pedal may feel soft, lack resistance, or go to the floor without disengaging the clutch.

3. Hydraulic Fluid Leaks

External leaks near the transmission bell housing are a common symptom of a bad slave cylinder. Leaking fluid can contaminate the clutch, causing slipping or chatter.

4. Loss of Clutch Function

A completely failed slave cylinder may result in a non-functional clutch pedal, rendering the vehicle undrivable.

5. Damage to Transmission or Clutch

Improper disengagement can damage gears, synchros, or prematurely wear the clutch disc.

Signs of a Worn or Failing Clutch Slave Cylinder

-

Difficulty engaging gears (especially first and reverse)

-

Clutch pedal feels soft or sinks to the floor

-

Visible brake fluid leakage near the bell housing

-

Low clutch fluid level in the reservoir

-

Air bubbles during bleeding

-

Clutch slipping due to fluid contamination

Timely diagnosis and repair are crucial to avoid transmission damage or full clutch system failure.

How to Replace a Clutch Slave Cylinder

Note: For CSC (concentric slave cylinders), transmission removal is required. For external types, replacement is simpler and can often be done without transmission removal.

Tools Needed:

-

Jack and jack stands

-

Brake fluid (usually DOT3 or DOT4)

-

Wrenches and sockets

-

Line wrench (for hydraulic fittings)

-

Bleeder kit

-

Safety gloves and eye protection

Steps for External Slave Cylinder Replacement:

-

Secure and Raise Vehicle

-

Park on a level surface, set the parking brake, and lift the vehicle using a jack. Secure with jack stands.

-

-

Locate and Disconnect Slave Cylinder

-

Follow the hydraulic line from the clutch master cylinder to the slave. Disconnect the fluid line carefully to prevent spillage.

-

-

Remove Old Slave Cylinder

-

Unbolt the mounting hardware and remove the cylinder.

-

-

Install New Slave Cylinder

-

Position the new slave and tighten bolts to manufacturer torque specs. Reconnect the fluid line.

-

-

Bleed the System

-

Use a bleeder kit or follow manual bleeding by opening the valve while depressing the clutch pedal. Remove all air for proper function.

-

-

Top Up Fluid and Test

-

Refill the clutch fluid reservoir and test the pedal feel. Ensure smooth gear engagement before driving.

-

Maintenance Tips

-

Always use the correct brake fluid type.

-

Regularly inspect hydraulic lines for cracks or leaks.

-

Bleed the clutch system any time it feels spongy or after repairs.

-

Replace the master cylinder or hose if symptoms persist after slave cylinder replacement.

-

For CSC systems, consider replacing the unit during clutch replacement, as it’s labor-intensive to access.

Follow us on Facebook for more parts.

Reviews

Clear filtersThere are no reviews yet.