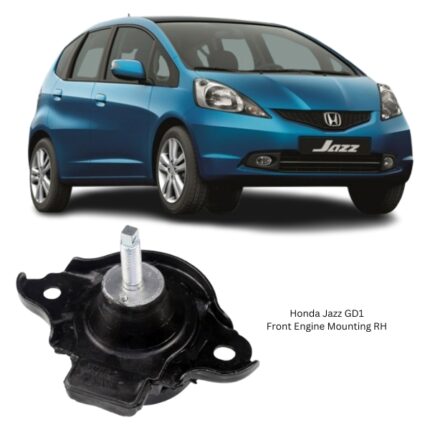

Get Honda Jazz GD1 Front Engine Mounting RH 50821-SAA-013 in Kenya

The Front Engine Mounting RH (Right-Hand Side) is a fundamental component within a vehicle’s engine support structure. It is designed to anchor the engine securely to the vehicle’s chassis while absorbing and isolating engine-induced vibrations, managing torque loads, and ensuring proper engine alignment. Located at the front-right position of the engine bay, this mount is part of a system that balances structural stability with comfort and precision in engine operation.

Engine mounts are subjected to a combination of static weight from the engine and dynamic forces from acceleration, deceleration, cornering, and rough road conditions. The RH front mount, in particular, often absorbs significant lateral and torsional forces due to its position in the engine bay, making its integrity vital to the vehicle’s overall performance and safety.

Core Purpose and Functionality

The Front Engine Mounting RH plays a crucial role in supporting the engine’s weight and restraining its movement under load. Its primary functions include:

-

Structural Engine Support: Carries part of the engine’s weight and keeps it properly seated within the engine compartment.

-

Vibration Isolation: Damps out engine vibrations to prevent them from reaching the vehicle’s frame and passenger cabin.

-

Torque Reaction Control: Minimizes engine movement caused by rotational torque, especially during gear shifts, acceleration, and deceleration.

-

Powertrain Alignment: Ensures proper alignment of the engine and transmission with the driveline for optimal operation.

-

System Protection: Prevents excessive engine movement that could damage hoses, belts, wiring, and surrounding components.

Together, these functions contribute to a smoother, quieter ride and protect the engine and vehicle systems from unnecessary wear.

Construction and Materials

The Front Engine Mounting RH is built from durable, heat-resistant, and fatigue-tolerant materials capable of withstanding the harsh operating conditions of the engine bay.

Main Components:

-

Metal Bracket or Housing

Typically manufactured from forged steel, aluminum, or high-strength sheet metal, this bracket connects to the vehicle chassis and provides structural integrity. -

Rubber or Elastomeric Insulator

The rubber core is designed to absorb and dampen engine vibrations. It is bonded to the metal parts via a vulcanization process and may use natural rubber or polyurethane, depending on the design. -

Central Bushing or Sleeve

This metal sleeve, often embedded within the rubber, allows a bolt to pass through the mount, providing a firm connection point while enabling slight, controlled movement. -

Hydraulic Damping System (optional)

Some mounts include a hydraulic fluid chamber that further enhances damping performance, especially at low frequencies such as engine idle. -

Protective Coating or Finish

Anti-corrosion coatings (e.g., zinc plating or powder coating) protect the metal from exposure to water, salt, and engine fluids. -

Thermal Shielding

In some cases, heat-resistant shields or coatings are added to protect the rubber element from radiant heat, particularly when the mount is positioned near exhaust systems.

These materials work in harmony to deliver both durability and comfort.

Performance Attributes

The effectiveness of a Front Engine Mounting RH is determined by its ability to:

-

Support Loads Reliably: Holds the engine securely under varying load conditions and maintains correct orientation.

-

Reduce NVH (Noise, Vibration, Harshness): Absorbs engine-generated disturbances before they are transferred to the chassis or cabin.

-

Endure Environmental Stress: Resists damage from heat, oil, and chemical exposure.

-

Maintain Flexibility Over Time: Performs consistently over thousands of driving cycles without cracking or permanent deformation.

-

Withstand Impact Loads: Absorbs shock loads from potholes or sudden vehicle movements without failure.

A well-functioning RH engine mount contributes to precise handling, quieter operation, and increased comfort.

Common Signs of Wear or Failure

Like any mechanical component, the Front Engine Mounting RH is subject to wear and degradation. Recognizing early warning signs can prevent more extensive damage to the vehicle:

-

Excessive Vibration

If the mount’s rubber core deteriorates, engine vibrations will be transmitted to the chassis, making the cabin feel rough—especially at idle. -

Clunking or Impact Noises

As the mount loses its ability to restrict motion, the engine may shift or rock under load, producing knocking sounds during acceleration or braking. -

Visible Rubber Cracking or Separation

Cracks, splits, or oil-soaked rubber are indicators of a failing mount. -

Engine Rocking or Leaning

The engine may tilt or move more than usual when revved, especially when shifting between drive and reverse. -

Hydraulic Fluid Leaks

On hydraulic mounts, leaking fluid from within the mount indicates internal failure. -

Wear on Adjacent Components

Misalignment or sagging may cause stress on exhaust pipes, radiators, and axle joints.

Immediate replacement of a compromised mount helps maintain drivability and safety.

Installation Overview

Installation of the Front Engine Mounting RH requires care, proper support of the engine, and correct torque specifications. The general process involves:

-

Prepare the Vehicle

Park on a flat surface, disconnect the battery, and allow the engine to cool. -

Support the Engine

Use a hydraulic jack with a wooden block under the oil pan or an engine support brace to relieve stress on the mount. -

Remove the Old Mount

Unbolt the old mount from both the engine bracket and chassis. Take note of orientation and mounting hardware. -

Inspect the Area

Check surrounding components for wear or damage, including adjacent mounts. -

Install the New Mount

Position the new RH mount precisely, insert bolts, and torque them according to manufacturer guidelines. -

Double-Check Alignment

Ensure the engine is level and properly aligned within the engine bay. -

Test Drive

After installation, start the engine and test for any abnormal movement, vibration, or sounds.

Inspection and Maintenance Tips

Though engine mounts are not serviceable, routine visual checks can prevent failures:

-

Look for cracks or deformation in the rubber insulator.

-

Ensure the mount is not soaked in oil or fluid.

-

Check for loosened bolts or corrosion.

-

Observe engine behavior under load or idle.

Regular inspection during scheduled maintenance ensures optimal performance.

Benefits of Timely Replacement

-

Enhanced Ride Quality

Eliminates vibration and harshness transferred into the cabin. -

Stabilized Engine Positioning

Prevents engine tilt, sagging, or misalignment. -

Reduced Noise and Vibration

Ensures quiet, smooth engine operation. -

Protection of Connected Components

Reduces strain on hoses, axles, sensors, and the exhaust system. -

Improved Vehicle Handling

Maintains drivetrain integrity and alignment for better control.

Follow us on Facebook for more parts.

Reviews

Clear filtersThere are no reviews yet.