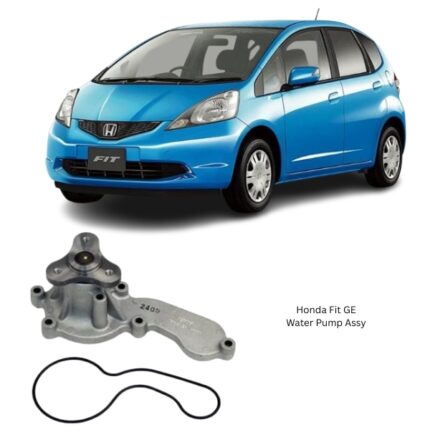

Get Honda Fit GE Water Pump Assy 19200-RB0-003 in Kenya

The Water Pump Assembly is a vital component of an engine’s cooling system, responsible for ensuring continuous circulation of coolant throughout the engine and radiator. Its function is to transfer heat away from the engine by moving coolant from the radiator into the engine block and back again. This steady flow of coolant helps prevent overheating, maintains optimal operating temperatures, and protects critical engine components from thermal stress.

Without a properly functioning water pump, the cooling system cannot effectively regulate temperature, which may lead to engine damage, reduced performance, or catastrophic failure. The water pump operates consistently while the engine is running, and is typically driven by the timing belt, serpentine belt, or a dedicated drive gear.

Purpose and Function

At its core, the water pump serves one essential function: to circulate coolant efficiently through the engine’s cooling system. The pump creates flow by using centrifugal force, pulling coolant from the radiator and pushing it through the engine block, cylinder head, and heater core before routing it back to the radiator to release absorbed heat.

Key Functions of the Water Pump Assembly Include:

-

Regulating Engine Temperature:

Helps maintain a consistent and optimal operating temperature, which improves combustion efficiency and engine performance. -

Preventing Overheating:

Reduces the risk of heat buildup in the cylinder head and block, which could lead to blown gaskets, warped heads, or engine seizure. -

Supporting Heater Operation:

Ensures hot coolant reaches the heater core for effective climate control inside the cabin. -

Protecting Lubrication System:

Maintains appropriate temperatures to prevent oil from thinning due to excessive heat, ensuring proper lubrication.

Construction and Materials

The Water Pump Assembly is designed to operate under high heat and pressure for extended periods, often in harsh engine environments. Therefore, it must be durable, corrosion-resistant, and precision-engineered.

Common Components of the Water Pump Assembly:

-

Housing (Pump Body):

Made of cast aluminum, cast iron, or high-strength thermoplastics. It houses the impeller, shaft, and bearing system. -

Impeller:

A rotor inside the housing, typically made of metal or composite material. It rotates to generate centrifugal force that propels the coolant through the system. -

Shaft and Bearing:

Connects the impeller to the pulley or drive gear. The bearing allows smooth rotation, while the shaft transmits mechanical energy from the drive source. -

Pulley or Gear Attachment:

Facilitates power input from the engine via a serpentine belt, timing belt, or chain. -

Seal (Shaft Seal or Gasket):

Prevents coolant from leaking around the rotating shaft. High-quality seals are resistant to heat and chemical exposure. -

Gasket or O-Ring:

Ensures a tight seal between the pump and the engine block to prevent coolant leaks.

High-performance or heavy-duty water pumps may include additional features like upgraded bearings, dual impellers, or reinforced shafts for extended durability.

Types of Water Pumps

There are several variations of water pumps depending on engine design and cooling system requirements:

-

Mechanical Water Pumps:

Driven directly by the engine (belt or gear). Common in most combustion engines. -

Electric Water Pumps:

Operate independently of engine speed, often controlled electronically for precise temperature regulation. Common in hybrid and high-efficiency vehicles. -

Variable Flow Pumps:

Adjust coolant flow based on engine load or temperature for improved efficiency.

Each type is designed for specific engine configurations, ensuring proper coolant volume and flow at all operating conditions.

Performance Benefits

Installing a high-quality Water Pump Assembly offers several important benefits for engine health and performance:

-

Consistent Engine Cooling:

Provides uniform heat dissipation for optimal engine function. -

Improved Fuel Efficiency:

Engines running at stable temperatures burn fuel more efficiently. -

Reduced Emissions:

Prevents overheating-related combustion issues that increase emissions. -

Extended Engine Life:

Keeps engine components like the head gasket, pistons, and cylinder walls within safe temperature ranges. -

Enhanced Reliability:

Reduces the risk of breakdowns due to overheating or coolant loss.

Symptoms of a Failing Water Pump

Water pumps, like all mechanical parts, wear out over time. Recognizing early signs of failure helps avoid costly engine damage.

Common Warning Signs Include:

-

Coolant Leaks:

Coolant pooling under the engine or visible dripping from the pump housing may indicate a worn seal or cracked housing. -

Overheating Engine:

Rising engine temperatures or warning lights may point to restricted coolant flow. -

Noisy Operation:

A worn bearing may cause grinding or whining noises from the front of the engine. -

Steam or High-Temperature Warning:

Steam from the radiator or under the hood suggests the engine is overheating, possibly due to pump failure. -

Wobbling Pulley or Shaft:

Excessive play may mean internal bearing failure, which can damage belts or pulleys. -

Corrosion or Rust Around the Pump:

Indicates long-term leakage or coolant contamination.

Promptly addressing these signs and replacing the water pump when needed helps avoid severe engine damage.

Installation Overview

Installing a Water Pump Assembly is a complex process that varies depending on engine layout, access, and whether it’s belt or gear-driven. It should be performed by qualified technicians or individuals with mechanical experience.

General Steps Include:

-

Drain the Coolant System:

Safely drain all coolant to avoid spills and contamination. -

Remove Engine Components:

Depending on location, removal of belts, pulleys, fan assemblies, and sometimes timing covers may be required. -

Unbolt and Remove the Old Water Pump:

Carefully disconnect hoses and mounting bolts. -

Clean the Mounting Surface:

Remove any old gasket material and inspect the sealing area for damage or corrosion. -

Install the New Water Pump Assembly:

Use a new gasket or sealant as recommended. Torque bolts to manufacturer specs. -

Reconnect Components and Refill Coolant:

Replace all removed parts, fill the system with coolant, and bleed air from the system. -

Test for Leaks and Proper Operation:

Run the engine, monitor temperature, and inspect for leaks.

In many cases, it’s advisable to replace the water pump alongside related components like the timing belt or thermostat for comprehensive service.

Maintenance and Longevity

To extend the life of your Water Pump Assembly and cooling system:

-

Use Quality Coolant:

Always use the recommended coolant type and change it at regular intervals to prevent corrosion and buildup. -

Inspect Belts and Pulleys:

Ensure that the drive belt is properly tensioned and free from cracks. -

Monitor Coolant Levels:

Low coolant may indicate leaks or system inefficiency. -

Avoid Overheating:

Stop driving immediately if the temperature gauge spikes or steam appears. -

Replace Seals and Gaskets When Needed:

Even a small leak can shorten pump life and affect cooling efficiency.

Follow us on Facebook for more parts.

Reviews

Clear filtersThere are no reviews yet.