-5%

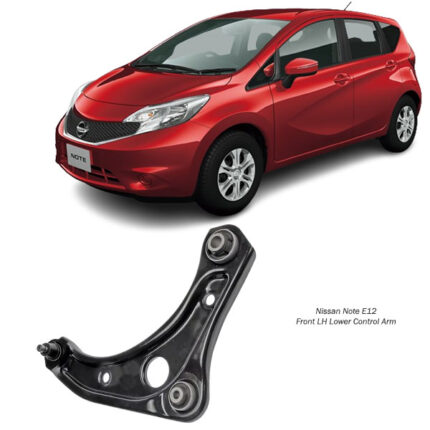

Get Front RH Track Control Arm Daihatsu Terios J100 4806887403

The front right-hand (RH) track control arm, also known as the lower control arm, is an integral component of a vehicle’s suspension system. It ensures stability, controls wheel movement, and supports the weight of the vehicle. Understanding the benefits of a properly functioning control arm and recognizing signs of wear can help maintain vehicle safety and performance.

Benefits of the Front RH Track Control Arm

-

Stability and Handling:

- Improved Stability: Track control arms help stabilize the movement of the wheels, minimizing lateral movement and maintaining consistent tire contact with the road surface. This enhances vehicle stability, especially during cornering and high-speed maneuvers.

- Reduced Body Roll: By controlling the lateral movement of the wheels, track control arms help reduce body roll and sway, enhancing overall handling and driver confidence. This results in more predictable and responsive steering behavior.

2. Suspension Geometry and Alignment:

- Preservation of Suspension Geometry: Track control arms play a critical role in maintaining proper suspension geometry, including camber, caster, and toe angles. This ensures even tire wear, optimal wheel alignment, and consistent handling characteristics.

- Prevention of Premature Tire Wear: Misaligned or worn track control arms can lead to irregular tire wear patterns, such as cupping or feathering, resulting in reduced tire lifespan and compromised handling performance. Proper maintenance and adjustment help prevent premature tire wear.

3. Enhanced Braking Performance:

- Optimal Tire Contact Patch: Properly functioning track control arms ensure consistent tire contact with the road surface, allowing for optimal brake performance and shorter stopping distances. This enhances vehicle safety and driver confidence, particularly during emergency braking maneuvers.

- Reduced Brake Dive: Track control arms help minimize brake dive, where the front of the vehicle dips forward during braking, by maintaining proper suspension geometry and weight distribution. This results in more controlled and predictable braking behavior.

4. Comfort and Ride Quality:

- Reduced Vibrations: Track control arms help absorb shocks and vibrations transmitted from the road surface to the vehicle’s chassis, resulting in a smoother and more comfortable ride for occupants. This minimizes driver fatigue and enhances passenger comfort, especially on long journeys.

- Improved Stability: By controlling wheel movement and minimizing lateral sway, track control arms contribute to overall ride stability, reducing the sensation of side-to-side motion and body roll. This creates a more pleasant and enjoyable driving experience.

5. Durability and Longevity:

- Robust Construction: Track control arms are typically constructed from high-strength materials such as steel or aluminum, offering excellent durability and resistance to fatigue and corrosion. This ensures long-term reliability and performance under various driving conditions.

- Resistance to Wear: Well-designed track control arms undergo rigorous testing to withstand the stresses and forces encountered during normal driving, including braking, acceleration, and cornering. This helps prevent premature wear and ensures consistent performance over time.

6. Customization and Performance Upgrades:

- Aftermarket Options: Enthusiasts can upgrade to performance-oriented track control arms featuring adjustable components, reinforced construction, or lightweight materials. These aftermarket upgrades offer enhanced durability, adjustability, and rigidity for improved handling and cornering performance.

- Track Performance: Upgraded track control arms are popular upgrades for enthusiasts participating in motorsport activities such as autocross, track days, or competitive racing. Performance-oriented control arms provide precise suspension adjustments and improved chassis rigidity for maximum performance.

Signs a Car Needs a New Front RH Track Control Arm

- Uneven Tire Wear:

- Excessive wear on the inner or outer edges of the front tires can indicate a problem with the lower control arm.

- Misalignment caused by a worn or damaged control arm can lead to uneven tire wear patterns.

- Steering Instability:

- If you notice increased play or looseness in the steering wheel, especially when driving over bumps or uneven surfaces, it could be a sign of a worn control arm.

- Steering instability might also manifest as a wandering sensation or difficulty maintaining a straight line while driving.

- Suspension Noise:

- Squeaking, creaking, or clunking noises from the front suspension area, particularly during cornering or driving over bumps, may indicate worn ball joints or bushings in the control arm.

- These noises result from excessive play or movement in the control arm components.

- Vibration or Shimmying:

- Experiencing vibrations or a shimmying sensation in the steering wheel or vehicle chassis, especially at high speeds, can signal a worn or damaged control arm.

- This vibration may result from improper alignment caused by a faulty control arm.

- Visible Damage or Corrosion:

- Inspect the front RH track control arm for visible signs of damage, such as cracks, bends, or corrosion.

- Rust or corrosion on the control arm can weaken its structural integrity, leading to premature failure.

- Persistent Alignment Issues:

- Continuous alignment problems, even after professional alignment service, may indicate underlying issues with the front RH track control arm.

- Difficulty achieving or maintaining proper alignment settings can be a sign of a worn or damaged control arm.

Follow us on Facebook for more parts.