-17%

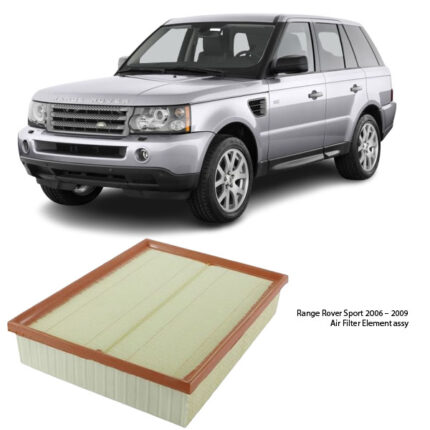

Get Range Rover Sport 2006 – 2009 Air Filter Element Assy PHE000112 in Kenya

The Front Engine Mount is a crucial component in your vehicle’s engine and transmission system. It plays a key role in securing the engine, absorbing vibrations, and ensuring smooth vehicle operation. Without a properly functioning engine mount, your car can experience excessive engine movement, vibrations, and potential damage to other components.

In this comprehensive guide, we’ll cover:

What a Front Engine Mount is

How it functions

Different types of engine mounts

Signs of a failing engine mount

When and how to replace it

Best brands and maintenance tips

Let’s get started!

What is a Front Engine Mount?

A Front Engine Mount is a component that secures the engine to the vehicle’s chassis while absorbing vibrations and movement caused by the engine’s operation. It is typically located at the front of the engine, near the radiator or cross-member, depending on the vehicle’s design.

Main Functions of a Front Engine Mount

Secures the Engine: Prevents excessive movement or shifting

Absorbs Vibrations: Reduces engine vibrations felt inside the cabin

Supports Load & Weight: Helps distribute the engine’s weight evenly

Prevents Damage: Protects engine and transmission components from excessive motion

Enhances Driving Comfort: Ensures a smooth and quiet ride

A well-functioning engine mount contributes to stability, noise reduction, and prolonged engine life.

How Does a Front Engine Mount Work?

The front engine mount is designed to hold the engine in place while absorbing torque and vibrations generated by the engine.

Metal Frame: Provides structural support and attachment points

Rubber or Polyurethane Bushing: Dampens vibrations and absorbs shock

Hydraulic Fluid (in hydraulic mounts): Further reduces vibrations and movement

When the engine is running, it generates rotational forces and vibrations. The engine mount absorbs these forces, preventing them from transferring to the chassis and passenger cabin.

Types of Front Engine Mounts

There are different types of front engine mounts, each designed for specific performance needs.

Rubber Engine Mounts

Most common type

Made of rubber to absorb vibrations

Affordable and durable

Ideal for standard passenger vehicles

Hydraulic Engine Mounts

Contains hydraulic fluid inside the rubber mount

Reduces vibrations more effectively than standard rubber mounts

Used in luxury and high-performance vehicles

More expensive but provides superior comfort

Polyurethane Engine Mounts

Made of stiffer polyurethane material

Offers better durability and performance

Ideal for high-performance and modified vehicles

Can transmit more vibrations compared to rubber mounts

Active Engine Mounts

Electronically controlled to adapt to engine vibrations

Uses sensors to adjust damping dynamically

Found in modern vehicles with adaptive suspension systems

More expensive but provides optimal ride comfort

The right type of engine mount depends on your vehicle type and driving needs.

Signs Your Front Engine Mount Needs Replacement

A failing front engine mount can lead to excessive vibrations, clunking noises, and misalignment issues. Here are the key warning signs:

Excessive Engine Vibrations: Increased vibrations inside the cabin and steering wheel

Engine Movement or Rocking: Engine tilts or shifts more than usual under acceleration or braking

Loud Clunking or Banging Noises: Noises when shifting gears or accelerating

Visible Wear or Damage: Cracks in the rubber, fluid leaks (from hydraulic mounts)

Misaligned Belts or Hoses: Engine movement can cause misalignment of accessories

Rough Idling: Unstable engine behavior while the car is stationary

If you notice any of these symptoms, it’s time to inspect and replace your front engine mount.

How Often Should You Replace Your Front Engine Mount?

Recommended Replacement Interval:

80,000 – 150,000 km (50,000 – 90,000 miles) under normal conditions

Earlier replacement if exposed to rough driving, heavy loads, or aggressive acceleration

Factors Affecting Lifespan:

Driving Conditions: Rough roads and frequent stop-and-go driving reduce lifespan

Engine Torque & Performance: High-performance engines put more stress on mounts

Weather & Temperature Changes: Extreme heat and cold can wear out rubber mounts faster

How to Replace a Front Engine Mount?

Replacing a front engine mount requires mechanical skills and proper tools.

Tools Needed:

Jack & jack stands

Socket & wrench set

Torque wrench

Pry bar & rubber mallet

New front engine mount

Step-by-Step Process:

Lift the Car & Secure the Engine – Use a jack to support the engine weight

Locate & Remove the Old Engine Mount – Unbolt it from the chassis and engine

Inspect for Additional Wear & Tear – Check surrounding components for damage

Install the New Engine Mount – Align it correctly and tighten bolts to specifications

Lower the Engine & Reassemble Components

Test Drive & Check for Vibrations – Ensure proper function

Caution: Incorrect installation can lead to engine misalignment, excessive vibrations, or damage to other components.

Best Front Engine Mount Brands

Maintenance Tips for Longer Engine Mount Life

Avoid Harsh Acceleration & Braking – Reduces stress on the mounts

Inspect for Leaks & Cracks Regularly – Spot issues early

Keep Engine Components Tight & Secure – Prevents excessive movement

Use Quality Engine Mounts – Cheap mounts can fail prematurely

Replace in Pairs (if needed) – Ensures balanced engine support

A well-maintained engine mount ensures a smooth, vibration-free driving experience.

Follow us on Facebook for more parts.