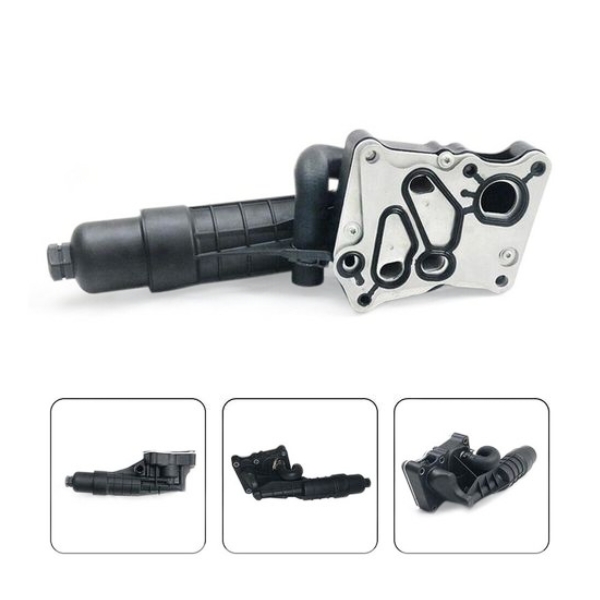

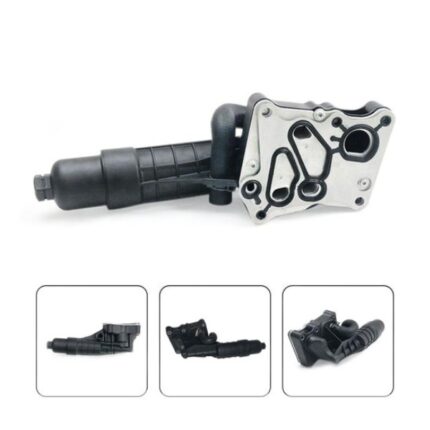

Get Mercedes M271 Engine Oil Transmission Oil Cooler 2711801410 in Kenya

An Engine Oil Transmission Oil Cooler is a vital automotive component designed to regulate the temperature of engine oil or transmission fluid, ensuring optimal performance, efficiency, and longevity of the vehicle’s drivetrain. By managing heat generated during engine combustion and transmission operation, the cooler prevents overheating, reduces friction, and helps maintain stable fluid viscosity. This results in smoother gear shifts, improved lubrication, and an overall increase in the durability of both engine and transmission systems.

Function and Purpose

The primary role of an engine oil transmission oil cooler is heat dissipation. Both the engine and the transmission generate significant amounts of heat due to friction, high-speed rotations, and fluid circulation. Excessive heat, if left unchecked, can lead to:

-

Oil breakdown, reducing its lubricating properties.

-

Increased wear on engine and transmission components.

-

Sluggish performance, as overheated oil loses viscosity.

-

Higher risk of failure, including transmission slip or engine seizure.

The cooler acts as a miniature radiator, channeling hot oil or transmission fluid through a series of finned tubes. These tubes allow air or coolant to absorb and carry away heat before the fluid is recirculated back into the engine or transmission. By maintaining a stable fluid temperature, the oil cooler ensures:

-

Optimal lubrication

-

Stable viscosity under varying loads

-

Extended service life of mechanical components

Construction and Design

An engine oil transmission oil cooler is typically built with the following features:

-

Core Assembly – Made up of a series of finned aluminum or copper tubes that maximize surface area for heat transfer.

-

Inlet and Outlet Ports – Designed to connect to the oil or transmission fluid lines, allowing seamless flow through the cooler.

-

Mounting Brackets – Provide secure attachment points within the engine bay or in front of the radiator.

-

Cooling Fins – Thin, lightweight fins around the tubes help dissipate heat efficiently by increasing airflow contact.

-

End Tanks/Headers – Hold and direct the fluid into the cooling core before recirculation.

Depending on vehicle design, oil coolers may be air-cooled (mounted in front of the radiator to rely on airflow) or liquid-cooled (using engine coolant to transfer heat from the oil).

Types of Oil Coolers

-

Engine Oil Coolers – Specifically designed to maintain engine oil at optimal temperature, preventing premature breakdown of lubrication under heavy loads or high-speed driving.

-

Transmission Oil Coolers – Focus on keeping transmission fluid cool, especially in automatic gearboxes where overheating can cause fluid oxidation and shifting problems.

-

Combination Coolers – Integrated systems capable of cooling both engine oil and transmission fluid, often found in performance vehicles and heavy-duty applications.

Benefits of an Oil Transmission Cooler

-

Prevents Overheating – Stabilizes oil and fluid temperatures during intense driving conditions.

-

Improves Performance – Maintains consistent lubrication for smoother gear changes and engine efficiency.

-

Extends Component Life – Reduces wear on bearings, gears, and seals by keeping oil within the right temperature range.

-

Boosts Reliability – Ideal for vehicles driven in hot climates, mountainous terrains, or under heavy loads such as towing.

-

Fuel Efficiency – A cooler engine and transmission work more efficiently, consuming less fuel.

Applications

Oil transmission coolers are used across a wide range of vehicles:

-

Passenger cars – To enhance reliability in everyday driving.

-

Performance cars – To cope with the heat generated during high-speed or track driving.

-

SUVs and 4x4s – Particularly in off-road conditions where strain on the engine and transmission is higher.

-

Commercial vehicles and trucks – Where long-distance hauling and towing place extra thermal stress.

-

Heavy machinery – Construction and agricultural equipment also benefit from oil coolers due to constant heavy loads.

Installation Considerations

When fitting an oil cooler, several factors are considered:

-

Location – Usually mounted at the front of the radiator or in areas with high airflow.

-

Compatibility – Designed to match the vehicle’s engine and transmission system specifications.

-

Connections – Proper hose fittings, clamps, and seals must be used to prevent leaks.

-

Maintenance access – Placement should allow easy inspection and cleaning.

Some vehicles come equipped with factory-installed oil coolers, while others may use aftermarket kits for added performance.

Maintenance and Care

Like any cooling system, an oil transmission cooler requires regular checks to ensure proper function. Key maintenance practices include:

-

Visual Inspections – Checking for leaks, cracks, or damage to fins and tubing.

-

Cleaning – Removing dirt, dust, and debris that may block airflow across cooling fins.

-

Hose and Connection Checks – Ensuring tight seals and no signs of fluid seepage.

-

Fluid Checks – Monitoring oil and transmission fluid levels, as low fluid may indicate a leak within the cooler system.

A well-maintained cooler can last for many years and significantly extend the service life of engine and transmission components.

Common Issues

-

Leaks – Damaged seals or corroded tubes can cause oil or fluid loss.

-

Blockages – Dirt or sludge buildup inside the cooler can restrict flow.

-

External Damage – Road debris, stones, or impacts can bend fins or puncture tubes.

-

Thermal Stress – Prolonged overheating can weaken material integrity over time.

Identifying and addressing these issues early prevents major repairs.

Signs of a Failing Oil Cooler

-

Engine or transmission running hotter than usual

-

Noticeable drop in oil pressure

-

Leaks under the vehicle near cooler lines

-

Slipping transmission (in automatic vehicles)

-

Unusual burning smell due to overheated oil

When such symptoms appear, prompt inspection and replacement are recommended.

Longevity and Reliability

A properly installed and maintained oil cooler can last as long as the vehicle itself. With durable construction and heat-resistant materials, modern oil coolers are built to withstand high pressures and constant thermal cycling. For vehicles operating in demanding environments, an oil cooler is not just an add-on but a crucial safeguard for long-term reliability.

Follow us on Facebook for more parts.

Reviews

Clear filtersThere are no reviews yet.