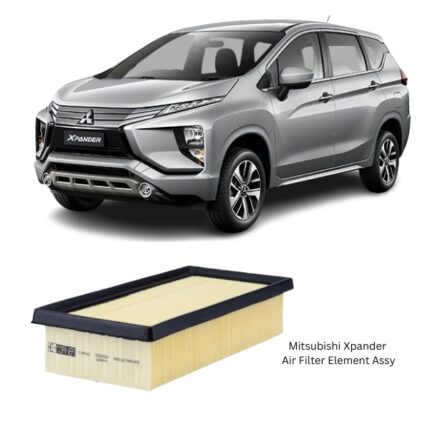

Get Mitsubishi Xpander Air Filter Element Assy 1500A687 in Kenya

An Air Filter Element Assembly is a vital component of a vehicle’s intake system, responsible for cleaning the air before it enters the engine. By trapping dust, dirt, pollen, and other airborne contaminants, it ensures that only clean, filtered air reaches the combustion chambers. This simple yet essential function plays a major role in preserving engine health, enhancing performance, and improving fuel efficiency.

1. Function and Importance

The engine in any modern vehicle requires a precise mix of air and fuel to operate efficiently. The quality of the incoming air directly affects combustion. Contaminants in the air, if allowed to enter the engine, can cause abrasion, wear, and premature failure of internal components such as cylinders, pistons, and valves.

The Air Filter Element Assembly acts as the first line of defense, removing harmful particles while maintaining a steady airflow. It strikes a balance between filtration efficiency (how well it captures contaminants) and flow resistance (how freely air passes through), ensuring the engine “breathes” properly without being choked.

2. Construction and Components

An Air Filter Element Assembly is typically composed of several carefully engineered parts:

a) Filter Media

The filter media is the heart of the assembly. Most modern air filters use pleated paper or synthetic fibers to maximize surface area for capturing particles. The media is designed to filter out particles as small as a few microns without significantly restricting airflow. Some filters use multi-layer designs to trap both large and microscopic particles efficiently.

b) Supporting Frame

A rigid frame, often made from molded plastic, polyurethane, or metal, holds the filter media in place. The frame maintains the filter’s shape under the pressure of incoming air, preventing collapse or deformation.

c) Sealing Gasket

Around the edge of the filter is a gasket made from rubber or foam. This gasket ensures a tight seal between the filter and the air filter housing, preventing unfiltered air from bypassing the element.

d) Protective Mesh or Screen

Many filters include a metal or plastic mesh over the filter media to provide extra support, especially during high airflow or dusty conditions.

3. Filtration Technology

Modern air filters utilize advanced filtration technologies to improve performance:

-

Cellulose Media: Economical and effective for standard driving conditions.

-

Synthetic Fiber Media: Offers better airflow, higher filtration efficiency, and improved resistance to moisture.

-

Nanofiber Layers: Extremely fine fibers that can trap even submicron particles, common in premium performance filters.

The pleated design increases the surface area, allowing the filter to trap more particles without compromising airflow.

4. Performance Benefits

A high-quality Air Filter Element Assembly provides multiple benefits:

-

Engine Protection: Prevents abrasive particles from causing wear and damage to internal components.

-

Fuel Efficiency: Ensures optimal air supply for combustion, helping the engine run efficiently.

-

Performance Stability: Maintains consistent engine power output by ensuring smooth airflow.

-

Emission Control: Helps reduce harmful emissions by ensuring complete combustion.

-

Longevity: Extends the service life of the engine and related components.

5. Common Contaminants Trapped

Air filters are designed to trap a variety of airborne particles, including:

-

Dust and dirt

-

Pollen

-

Soot and exhaust residue

-

Insects and small debris

-

Road salt particles

-

Industrial pollution particles

By removing these contaminants, the filter ensures cleaner air enters the engine, improving overall performance.

6. Service Life and Replacement Intervals

The lifespan of an Air Filter Element Assembly varies depending on driving conditions, filter quality, and environmental factors.

-

Normal driving conditions: Replacement every 15,000 to 20,000 kilometers.

-

Dusty or off-road environments: Replacement as frequently as every 5,000 to 10,000 kilometers.

-

Manufacturer recommendations: Always follow the specific guidelines provided for your vehicle.

A clogged or dirty filter can restrict airflow, causing poor fuel economy, sluggish acceleration, and increased engine strain.

7. Signs of a Worn or Clogged Air Filter

It’s important to recognize when an air filter needs replacement. Common signs include:

-

Reduced engine performance

-

Decreased fuel economy

-

Black smoke from the exhaust

-

Unusual engine sounds or rough idling

-

Visible dirt or discoloration on the filter media

-

Check Engine Light triggered due to airflow sensor readings

8. Installation and Maintenance

Replacing an Air Filter Element Assembly is generally straightforward:

-

Locate the Air Filter Housing: Usually found near the engine intake manifold.

-

Open the Housing: Release clips, screws, or clamps.

-

Remove Old Filter: Take note of the filter’s orientation.

-

Clean Housing: Wipe away any dirt or debris inside.

-

Install New Filter: Ensure it’s seated correctly and the gasket forms a tight seal.

-

Secure Housing: Close the cover and fasten it properly.

Maintenance is minimal — apart from regular replacement, it’s recommended to occasionally inspect the filter, especially before long trips or during seasonal changes.

9. Environmental and Operational Considerations

The performance of an Air Filter Element Assembly can be affected by:

-

Climate: Hot, dry climates often have more dust; humid climates may introduce moisture into the filter.

-

Driving Habits: Stop-and-go traffic and urban driving often expose filters to more pollution.

-

Terrain: Off-road or rural driving environments expose the filter to heavier dust loads.

Eco-conscious disposal is important, as used filters contain trapped pollutants. Many auto service centers offer proper recycling.

10. Design Standards and Testing

High-quality Air Filter Element Assemblies are tested for:

-

Filtration Efficiency: Percentage of particles captured at various sizes.

-

Airflow Restriction: Resistance created by the filter at specific air volumes.

-

Dust Holding Capacity: The amount of dirt the filter can hold before performance drops.

-

Structural Integrity: Ability to withstand pressure, vibration, and temperature variations.

Filters meeting strict ISO, SAE, or equivalent standards ensure consistent and reliable performance.

11. Advantages of a Quality Air Filter Element Assembly

-

Reliable engine protection in all driving conditions

-

Improved throttle response and acceleration

-

Extended lifespan of mass airflow sensors and other intake components

-

Reduced wear on pistons, cylinders, and valves

-

Better fuel economy and lower emissions

Follow us on Facebook for more parts.

Reviews

Clear filtersThere are no reviews yet.