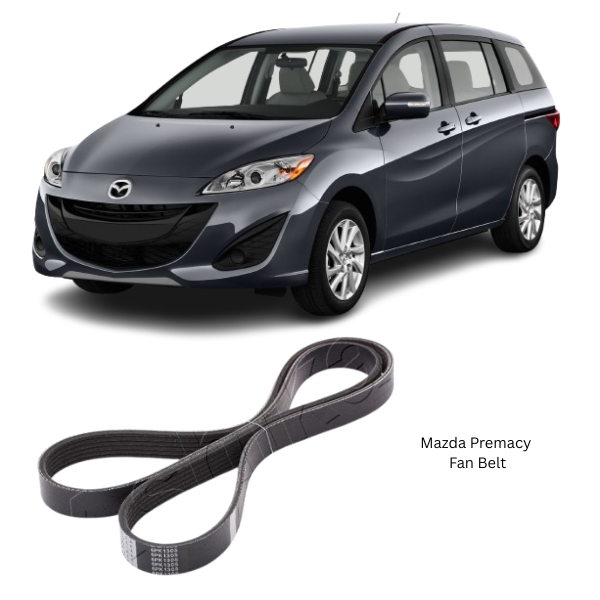

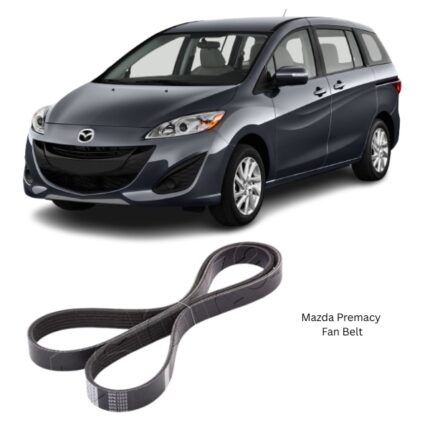

Get Mazda Premacy Fan Belt 6PK1305 in Kenya

A fan belt is one of the most essential components in an engine’s accessory drive system, acting as the vital link between the engine crankshaft pulley and various auxiliary components. While it is commonly called a “fan belt” due to its historical role in driving the engine’s cooling fan, modern designs often operate multiple accessories such as the alternator, water pump, power steering pump, and air conditioning compressor. In many vehicles, the traditional single-purpose fan belt has evolved into a multi-ribbed drive belt, but the basic principle remains the same — transferring mechanical power from the engine to critical components.

Function and Importance

The primary function of a fan belt is to transmit rotational energy from the engine’s crankshaft to various engine-driven accessories. When the engine runs, the crankshaft turns the belt, which in turn spins the pulleys attached to auxiliary systems. This ensures that:

-

The alternator produces electrical power to charge the battery and run the vehicle’s electrical systems.

-

The water pump circulates coolant through the engine and radiator, preventing overheating.

-

The power steering pump assists in steering effort, making the vehicle easier to handle.

-

The air conditioning compressor pressurizes refrigerant, enabling climate control inside the cabin.

Without a properly functioning fan belt, these systems would stop working, leading to rapid overheating, loss of electrical charging, heavy steering, and the absence of air conditioning.

Design and Construction

Modern fan belts are typically made from reinforced synthetic rubber compounds to withstand constant bending, high tension, and exposure to engine heat and fluids. The most common materials include:

-

EPDM Rubber (Ethylene Propylene Diene Monomer):

Known for excellent heat, ozone, and weather resistance, EPDM belts have a long service life compared to older neoprene belts. -

Cord Reinforcement:

High-strength polyester, Kevlar®, or fiberglass cords are embedded inside the belt to provide tensile strength, preventing stretching and maintaining proper tension. -

Multi-Ribbed Surface:

Many fan belts have multiple longitudinal ribs that increase surface contact with the pulley grooves, reducing slippage and improving power transfer efficiency.

The belt is designed to operate quietly, resist cracking, and maintain flexibility even in extreme temperature variations.

Types of Fan Belts

Although the term “fan belt” is often used generally, there are several variations:

-

V-Belt:

A single-rib, wedge-shaped belt used in older vehicles and some machinery. It fits into a matching V-shaped pulley groove, providing strong grip. -

Serpentine Belt:

A single, continuous multi-ribbed belt that snakes around multiple pulleys. This design reduces the number of belts needed and simplifies maintenance. -

Cogged or Notched V-Belt:

A V-belt with molded notches that improve flexibility, allowing it to bend more easily around smaller pulleys. -

Multi-Belt Systems:

Some engines use separate belts for different accessories, for example, one belt for the alternator and water pump, and another for the power steering pump.

Operation

The fan belt relies on frictional contact between its surface and the pulleys to transmit torque. Proper tension is critical — too loose, and the belt will slip, reducing performance and causing noise; too tight, and it may place excessive strain on bearings, leading to premature wear of accessories.

Modern systems often use an automatic belt tensioner, which maintains optimal tension without the need for manual adjustment. This tensioner also compensates for belt stretch over time.

Signs of Wear or Failure

A fan belt is a wear item that gradually degrades due to constant mechanical stress and exposure to heat, oil, coolant, and dust. Common signs that a belt may need replacement include:

-

Cracks or Fraying: Visible surface damage, particularly along the ribs or edges.

-

Glazing: A shiny, hardened surface caused by overheating or slippage.

-

Noise: A squealing or chirping sound, often more noticeable during engine startup or when accessories engage.

-

Loss of Function: Dimming headlights, overheating, or heavy steering may occur if the belt is slipping or has snapped.

-

Vibration or Flutter: Irregular belt movement due to misalignment or pulley wear.

Consequences of Fan Belt Failure

If a fan belt breaks while driving, several systems can fail simultaneously. The alternator will stop charging, leading to battery depletion. The water pump will cease circulating coolant, causing the engine temperature to rise quickly and potentially leading to overheating damage such as warped cylinder heads or blown gaskets. If the belt drives the power steering pump, steering effort will suddenly increase, making the vehicle harder to control. For these reasons, a failed fan belt can immobilize a vehicle and cause costly repairs if not addressed promptly.

Maintenance and Replacement

To ensure reliable operation, the fan belt should be inspected at regular service intervals. Key maintenance practices include:

-

Visual Inspection: Look for cracks, frays, missing ribs, or contamination by oil or coolant.

-

Tension Check: For manually adjusted belts, ensure the correct deflection using manufacturer specifications.

-

Pulley Alignment: Misaligned pulleys can cause premature wear and noise.

-

Tensioner Condition: Inspect the belt tensioner for smooth operation and proper spring force.

Modern EPDM belts can last 80,000 to 100,000 kilometers or more, but inspection is still recommended every service, as environmental factors and accessory load can shorten their lifespan.

When replacing a fan belt, it’s best to follow the original routing diagram, which may be displayed on a label in the engine bay or in the service manual. If a serpentine belt is involved, the tensioner must be released to remove and install the belt.

Advantages of a Well-Maintained Fan Belt

A properly functioning fan belt offers:

-

Reliable Engine Cooling: Continuous operation of the water pump.

-

Steady Electrical Supply: Consistent alternator performance for vehicle electronics.

-

Comfortable Driving: Power steering assistance and air conditioning function.

-

Reduced Repair Costs: Prevents breakdowns and related damage.

-

Efficient Power Transfer: Minimal slippage means less wasted energy.

Environmental and Operational Challenges

Fan belts operate in a challenging environment, facing:

-

High Temperatures: From engine heat and under-hood conditions.

-

Chemical Exposure: Oil, coolant, and cleaning solvents can weaken rubber.

-

Mechanical Stress: Constant bending and tension cycles.

-

Contamination: Dust and debris can accelerate wear.

Modern belt materials are engineered to handle these stresses, but no belt is immune to eventual degradation.

Upgrades and Improvements in Design

Over the years, fan belts have benefited from significant improvements in material science and design:

-

EPDM Compounds: Offer greater resistance to cracking and hardening compared to older neoprene belts.

-

Noise-Reducing Rib Profiles: Reduce squeal and improve engagement with pulleys.

-

Durability Enhancements: Reinforced cords increase lifespan and maintain proper tension.

-

Self-Adjusting Tensioners: Eliminate manual adjustments and reduce the risk of improper installation.

Follow us on Facebook for more parts.

Reviews

Clear filtersThere are no reviews yet.