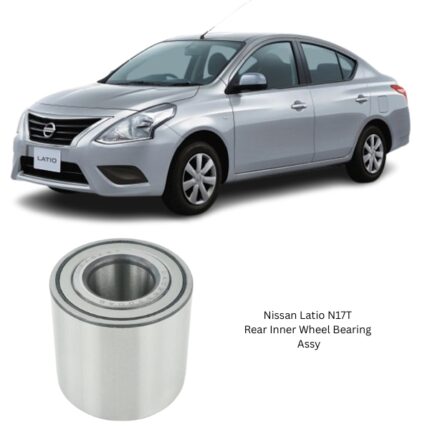

Get Nissan Latio N17T Rear Inner Wheel Bearing Assy DAC25550048 in Kenya

The Rear Inner Wheel Bearing Assembly is a critical component in the automotive wheel-end system, responsible for enabling smooth, stable, and low-friction rotation of the rear wheel hub relative to the axle shaft. Positioned on the inboard side of the wheel hub and mounted within the wheel hub carrier or axle housing, the rear inner wheel bearing plays a central role in managing radial and axial loads, ensuring drivetrain efficiency, and preserving vehicle handling performance.

Manufactured to meet stringent tolerances and load-bearing capacities, the rear inner bearing assembly supports the vehicle’s weight, absorbs forces generated during cornering, braking, and acceleration, and contributes directly to ride comfort, wheel alignment, and component longevity.

Core Functionality

The Rear Inner Wheel Bearing Assembly serves several essential functions:

-

Load Support: It bears radial loads (vertical forces from vehicle weight) and axial loads (lateral forces from cornering or braking), ensuring stable rotation of the wheel relative to the axle shaft or stub axle.

-

Rotational Efficiency: The bearing facilitates low-friction rotation of the wheel hub, reducing energy loss and mechanical resistance between moving parts.

-

Vibration Damping: Properly seated and lubricated, the bearing dampens vibrations and road shocks transmitted through the suspension and wheel, improving ride quality and vehicle control.

-

Component Alignment: It maintains precise alignment of the rear wheel in relation to the vehicle chassis, directly affecting tire wear, handling, and safety.

Design and Construction

The rear inner wheel bearing assembly typically features a tapered roller bearing or ball bearing construction, depending on the vehicle’s load-bearing requirements and design. The assembly includes several critical components:

-

Inner Race (Cone): Fits over the axle shaft or spindle and rotates with the wheel.

-

Outer Race (Cup): Pressed into the wheel hub or housing, remaining stationary.

-

Rolling Elements (Balls or Rollers): Placed between the races, these elements transfer loads and allow smooth rotation.

-

Cage (Retainer): Maintains the separation and alignment of rolling elements.

-

Seals/Shields: Protect the internal bearing elements from contamination by water, dust, and debris, and help retain lubricant.

In applications requiring high load capacity and durability, tapered roller bearings are often used due to their ability to handle both radial and thrust loads. For lighter applications or compact designs, deep groove ball bearings may be employed.

Material Specifications

The bearing components are made from high-grade, hardened bearing steel, such as SAE 52100 chrome steel, which provides exceptional hardness, wear resistance, and fatigue strength. The races and rolling elements undergo precision grinding and heat treatment to achieve smooth surfaces and consistent tolerances essential for low-friction operation and long service life.

The seals are typically constructed from synthetic rubber or high-temperature-resistant polymers, while the cage may be made from steel, brass, or engineered polymer composites, depending on application requirements.

Lubrication and Sealing

Proper lubrication is vital for bearing performance. Most rear inner wheel bearing assemblies are either:

-

Grease-packed and sealed: These are pre-lubricated at the factory and require no maintenance for the duration of their lifespan. They are protected by integrated seals to prevent lubricant loss and contamination ingress.

-

Serviceable (repackable): In some rear axle designs, the bearing is not sealed and requires periodic grease replenishment. This type often uses external seals and may be paired with a grease fitting or accessed during scheduled maintenance.

Grease specifications usually involve high-temperature wheel bearing grease with properties such as:

-

High drop point

-

Water resistance

-

Extreme pressure (EP) additives

-

Anti-corrosion inhibitors

Installation Considerations

The proper installation of a rear inner wheel bearing is critical for ensuring its performance and longevity. Key installation guidelines include:

-

Clean Environment: Bearings must be installed in a contaminant-free environment to prevent dirt or debris from damaging raceways or rolling elements.

-

Correct Press Fit: The bearing outer race should be pressed evenly into the hub or housing, and the inner race must be correctly seated on the shaft to avoid misalignment or binding.

-

Torque Specifications: When assembling bearing-related components (axle nuts, retaining bolts, spacers), follow the manufacturer’s torque guidelines to avoid excessive preload or clearance, which can lead to premature failure.

-

Lubrication Quality: If not pre-lubricated, only use the recommended bearing grease, evenly packed around the rollers or balls without overfilling.

-

Axial Spacers and Retainers: In adjustable bearing systems, proper use of shims or spacers ensures the correct end-play or preload is achieved.

Operational Performance

Once installed, the rear inner wheel bearing must withstand:

-

Rotational speeds: Depending on vehicle use, from city driving to highway speeds.

-

Varying loads: Changes in vehicle weight due to passengers or cargo.

-

Thermal cycles: Continuous exposure to heating and cooling from driving conditions and brake system proximity.

-

Road shocks and vibrations: Caused by potholes, uneven surfaces, and acceleration or braking forces.

The bearing must maintain consistent rolling performance without developing excessive play, noise, or temperature increases during its service life.

Maintenance and Inspection

While sealed rear inner bearings require no maintenance, serviceable bearings should be inspected at regular intervals. Key inspection procedures include:

-

Visual check for grease leakage

-

Manual rotation to detect roughness or resistance

-

Checking for play or looseness in the wheel hub

-

Listening for humming or grinding noises during driving

When symptoms of bearing wear or failure are present, prompt replacement is advised to avoid safety risks such as wheel wobble, brake system misalignment, or hub seizure.

Failure Modes and Prevention

Common causes of rear inner wheel bearing failure include:

-

Improper installation or preload

-

Water or debris contamination

-

Overheating from lack of lubrication

-

Impact damage from potholes or accidents

-

Extended service beyond recommended lifespan

Preventive measures involve proper installation practices, regular inspections, and using high-quality OEM or OE-equivalent bearing assemblies.

Follow us on Facebook for more parts.

Reviews

Clear filtersThere are no reviews yet.