-12%

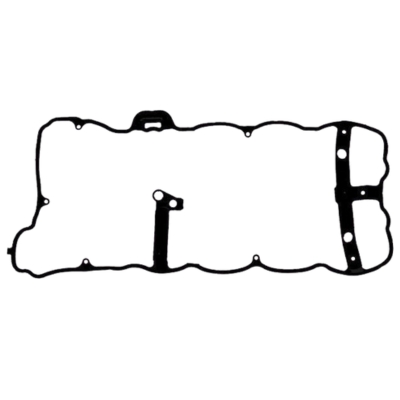

Get Top Cover Gasket Cylinder For 1NR-FE Engines 11213-47020 in Kenya

The Top Cover Gasket, also known as the Cylinder Head Cover Gasket or Rocker Cover Gasket, is an essential sealing component in an internal combustion engine. Positioned between the cylinder head and the valve cover (also referred to as the top cover), this gasket serves a critical role in maintaining engine performance, cleanliness, and reliability. Its primary function is to prevent oil leakage from the top portion of the engine, particularly where the camshaft, rocker arms, and valve train components operate under high-speed and high-temperature conditions.

While relatively simple in form, the top cover gasket plays a highly significant role in the overall integrity of the engine. Failure of this gasket can result in oil leaks, contamination of engine components, poor engine performance, or even damage to surrounding systems.

Component Placement and Role

The top cover gasket is installed between the valve cover and the cylinder head. The valve cover is bolted on top of the engine to protect internal moving parts of the valvetrain from debris, moisture, and oil spillage. Inside this chamber, engine oil is distributed for lubricating the camshaft, rocker arms, and valves.

The top cover gasket provides a seal along the mating surface between the cylinder head and the valve cover, ensuring:

-

Oil retention: Prevents engine oil from seeping out.

-

Contaminant exclusion: Blocks dust, debris, and moisture from entering.

-

Pressure containment: Maintains correct internal pressure during engine operation.

-

Heat resistance: Withstands engine temperatures that fluctuate between cold starts and peak loads.

Material Composition

Modern top cover gaskets are engineered from materials that balance flexibility, heat resistance, chemical compatibility, and durability. Common materials include:

-

Molded Rubber (Nitrile or Silicone)

Widely used due to its ability to retain elasticity, seal effectively, and resist oil degradation. Silicone rubber gaskets offer excellent heat tolerance and longevity in harsh environments. -

Cork Composite

A traditional material often reinforced with rubber. It provides a good seal and compressibility, although it may degrade more rapidly in high-temperature applications. -

Thermoplastic Elastomer (TPE)

Offers a balance between flexibility and thermal resistance. These gaskets are molded for precision fit and long-term sealing reliability. -

Multi-Layer Steel (MLS)

Occasionally used in performance or high-pressure applications, especially in engines where precision sealing is critical.

The gasket’s design may include integrated grommets, beads, or metal reinforcements to enhance fitment and reduce deformation under bolt load.

Design Features and Geometry

Top cover gaskets are typically custom-molded to match the perimeter geometry of the valve cover and the cylinder head. The design takes into account:

-

Bolt hole placement

-

Spark plug tube seals (in overhead cam engines)

-

Camshaft position sensor ports

-

Sealing ridges and ribs

-

Oil return path clearances

In engines where spark plugs are positioned in the center of the valve cover (common in inline-four or inline-six engines), the gasket set may include inner spark plug tube seals. These are crucial to prevent oil from seeping into the spark plug wells, which can cause misfires, electrical shorts, and reduced engine efficiency.

Functional Requirements

A top cover gasket must fulfill several functional requirements under operating conditions:

-

Sealing Performance

The gasket must form a tight, leak-free seal throughout the full temperature cycle of the engine—from cold starts to peak thermal loads. -

Compression Set Resistance

It must resist permanent deformation or flattening under sustained pressure, ensuring continued sealing effectiveness. -

Oil and Chemical Resistance

The gasket should withstand constant exposure to engine oil, fuel vapors, and other chemical compounds without swelling, cracking, or breaking down. -

Thermal Cycling Tolerance

It must endure repetitive heating and cooling without losing flexibility or adhesive properties. -

Vibration Dampening

Must maintain its seal integrity despite engine vibrations and minor shifts in valve cover alignment.

Installation and Torque Considerations

Correct installation of the top cover gasket is essential for effective sealing. The following best practices are observed during installation:

-

Surface Cleaning

Both the cylinder head and valve cover mating surfaces should be free from oil, old gasket material, and debris. Cleaning with a non-residue solvent is recommended. -

Gasket Alignment

The gasket should be aligned properly with the valve cover and cylinder head to ensure correct fitment and no overhangs or misalignments. -

Torque Specification

Valve cover bolts must be torqued evenly and to the manufacturer’s specification. Over-torquing can crush or deform the gasket, while under-torquing can result in leaks. -

Use of Sealant

In some engines, a small amount of RTV silicone sealant may be applied at specific corners or joints (e.g., camshaft junctions) to enhance sealing.

Improper installation can lead to gasket failure, oil leakage, and even damage to ignition components if oil contaminates the coil packs or spark plug chambers.

Signs of Gasket Failure

Over time, the top cover gasket may deteriorate due to prolonged exposure to heat, oil, and vibration. Common symptoms of gasket failure include:

-

Visible oil leaks around the valve cover

-

Burning oil smell, especially when oil drips onto the exhaust manifold

-

Engine misfires due to oil contamination of spark plugs

-

Low engine oil levels from gradual leakage

-

Check engine light caused by misfire or poor combustion

Regular inspection during routine maintenance or oil changes can help identify early signs of failure before significant damage occurs.

Service Life and Maintenance

The service life of a top cover gasket varies based on material, engine design, and operating conditions. On average, rubber or silicone gaskets last 60,000 to 100,000 kilometers before signs of wear emerge. However, exposure to extreme heat, poor installation, or poor quality engine oil can shorten lifespan significantly.

Periodic inspection and timely replacement ensure continued engine cleanliness, prevent oil loss, and maintain optimal engine function. It is also common practice to replace the gasket during valve adjustments, spark plug changes, or top-end overhauls.

Follow us on Facebook for more parts.

Reviews

Clear filtersThere are no reviews yet.