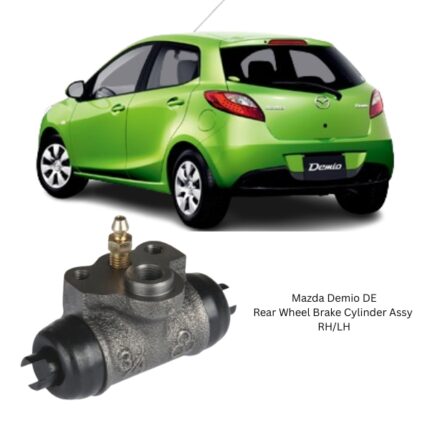

Get Mazda Demio DE Rear Wheel Brake Cylinder Assy RH/LH D651-26-610 in Kenya

The Rear Wheel Brake Cylinder Assembly RH/LH is a critical hydraulic component found in drum brake systems. Positioned on each side of the rear axle—right-hand (RH) and left-hand (LH)—these twin components are designed to convert the hydraulic pressure generated by the master cylinder into mechanical force. This mechanical action spreads the brake shoes outward against the inner drum surface, creating the necessary friction to reduce speed or bring the vehicle to a full stop.

Together, the RH and LH brake cylinders provide balance, symmetry, and responsiveness to rear braking. Their performance directly affects brake pedal feel, rear brake effectiveness, and overall vehicle safety under braking loads.

Purpose and Role in the Brake System

Rear wheel brake cylinders operate as miniature hydraulic actuators. Their job is to respond immediately to pressurized brake fluid delivered through the brake lines when the driver applies the brake pedal. This fluid pushes two internal pistons outward inside the wheel cylinder. Each piston contacts a brake shoe, forcing them apart and pressing their friction surfaces against the rotating drum.

This mechanical engagement generates the resistance required to slow or stop wheel rotation. Once the driver releases the brake pedal, return springs pull the brake shoes back to their resting positions, allowing the pistons to retract. Brake fluid pressure drops back to neutral, and the brake cylinder returns to standby mode, ready for the next application.

With one brake cylinder installed at each rear wheel (RH and LH), both sides of the axle are covered. Proper performance from each side ensures even brake force distribution, which is critical for vehicle control and safety—particularly under heavy braking or emergency stops.

Core Components and Structure

A rear wheel brake cylinder assembly includes the following major parts:

-

Cylinder Housing: Often made of cast iron, aluminum alloy, or corrosion-resistant steel, this robust casing forms the main body where fluid pressure is applied.

-

Dual Pistons: These small cylindrical components are positioned at either end of the cylinder bore. They receive hydraulic force and transfer it to the brake shoes.

-

Seals (Cup Seals): Internal rubber seals keep brake fluid pressurized and prevent leakage during piston movement.

-

Dust Boots: Flexible external covers protect the pistons and cylinder bore from contamination by water, dirt, or brake dust.

-

Brake Line Port: The connection point for the hydraulic brake line that brings in pressurized fluid from the master cylinder.

-

Bleeder Screw: A small valve used for bleeding air from the brake system during servicing or installation.

The RH and LH versions of the assembly are usually mirror images of each other in terms of orientation but perform the exact same function.

Material and Build Quality

Rear brake cylinders are engineered for endurance. They must withstand repeated thermal cycling, fluid pressure, road vibrations, and exposure to contaminants. Premium materials used in manufacturing include:

-

Cast iron or anodized aluminum for the body, ensuring rigidity and corrosion resistance.

-

EPDM rubber seals capable of tolerating brake fluid without degrading.

-

Steel or polymer pistons that resist wear and deliver smooth, frictionless movement.

-

Galvanized components to inhibit rust in humid or rainy conditions.

The choice of material directly influences the cylinder’s longevity and performance over time.

Operation in Daily Use

When functioning correctly, both the RH and LH cylinders contribute to:

-

Consistent brake shoe engagement

-

Balanced rear brake force

-

Even brake wear on both rear wheels

-

Stable and responsive brake pedal behavior

Even minor defects—such as a leaking seal or a sticky piston—can throw off brake balance and lead to irregular stopping behavior or premature brake shoe wear.

Installation Overview

Installing rear wheel brake cylinder assemblies typically follows these steps:

-

Vehicle elevation and wheel removal to access the rear drum assembly.

-

Drum removal to expose internal components, including the old brake cylinder.

-

Brake line disconnection, taking care not to damage threads or crush fittings.

-

Removal of mounting bolts holding the old cylinder to the backing plate.

-

Installation of new cylinder, aligning it precisely with the brake shoes and hydraulic line.

-

Reconnection of the brake line, and reassembly of the drum hardware.

-

Bleeding of the brake system to expel air and ensure hydraulic continuity.

-

Brake fluid refill and final inspection for leaks or softness in the pedal.

-

Test driving to confirm normal braking behavior from both rear wheels.

Proper installation of both RH and LH assemblies is key to preserving system symmetry and full braking power.

Signs of Wear or Failure

Though built for durability, these hydraulic components will eventually wear out or fail. Recognizing early warning signs can prevent further damage or compromised braking:

-

Brake fluid leaks on the inner wheel area or inside the drum.

-

Spongy or soft brake pedal due to loss of hydraulic pressure.

-

Pulling during braking, indicating uneven force between left and right cylinders.

-

Brake warning light activation caused by fluid level drops.

-

Streaked or soaked brake shoes, often a sign of seal failure inside the cylinder.

Routine inspections, especially during brake servicing, help catch such problems before they escalate.

Maintenance Tips

-

Visual inspections during service can reveal leaking fluid, torn dust boots, or seized pistons.

-

Brake fluid replacement every 1–2 years helps reduce internal corrosion and seal deterioration.

-

Clean drum interiors to prevent dirt buildup around the pistons.

-

Replace contaminated brake shoes when fluid leakage is detected, as soaked shoes lose friction.

Following a maintenance schedule can significantly extend the lifespan of the wheel cylinder assemblies.

Performance Contribution

Rear brake cylinders (RH and LH) serve a vital role in the rear brake system’s overall functionality. They ensure:

-

Balanced stopping power across both rear wheels

-

Smooth brake pedal modulation

-

Reduced wear and tear on brake components

-

Improved stability during cornering and emergency braking

Even with front disc brakes doing most of the work, the rear drum system provides essential support—especially when the vehicle is loaded or traveling downhill. In such scenarios, the wheel cylinders’ role becomes even more pronounced.

Follow us on Facebook for more parts.

Reviews

Clear filtersThere are no reviews yet.