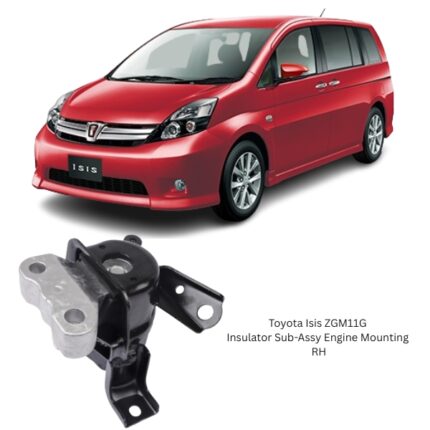

Get Toyota Isis ZGM11G Engine Mounting RH 12305-37050 in Kenya

The Insulator Sub-Assembly Engine Mounting RH (Right-Hand Side) is a critical component in the engine support system of a vehicle, serving the dual role of anchoring the engine securely to the chassis while simultaneously insulating the vehicle from unwanted vibrations and shocks. Positioned on the right-hand side of the engine bay (from the driver’s perspective), this mount is one of the most load-bearing and torque-resistant among the engine mounts, making it vital for both stability and performance.

As engine design has evolved to favor lightweight materials and improved NVH (Noise, Vibration, and Harshness) control, the right-hand engine mounting insulator has become more specialized, incorporating vibration-damping materials and hydraulic or fluid-filled designs. Its job is not just to hold the engine in place—it plays a critical role in preserving drivetrain alignment, reducing noise, and extending the lifespan of other vehicle components.

Purpose and Functionality

Every time the engine runs, it generates torsional forces, vibration, and movement due to internal combustion and the reciprocating motion of pistons. The RH Insulator Sub-Assy Engine Mount absorbs these forces, protecting the chassis and cabin from their effects.

Its core functions include:

-

Load Bearing: Supports the engine’s weight and counters the torque reaction forces, especially from the side of the engine typically under higher stress.

-

Vibration Isolation: Dampens both low- and high-frequency vibrations that would otherwise be transmitted to the passenger cabin.

-

Torque Management: Prevents engine rotation under acceleration or gear shifting, keeping the drivetrain aligned and reducing stress on components.

-

Chassis Protection: Prevents damage to the vehicle frame and nearby systems by limiting excessive engine movement.

-

Ride Comfort Improvement: Maintains a smoother, quieter ride by reducing engine harshness and cabin buzz.

The right-hand engine mount is especially important in front-wheel drive and transverse engine layouts where torque reactions are higher on that side.

Design and Construction

The Insulator Sub-Assy Engine Mounting RH is typically constructed with a combination of metal, rubber, and sometimes hydraulic damping elements to provide strength, flexibility, and vibration control.

Key Components:

-

Outer Bracket or Housing

This metallic structure (usually made from high-grade steel or cast aluminum) mounts directly to the engine block or subframe, forming the core support base. -

Rubber or Polyurethane Isolator

The elastomeric insulator absorbs vibration and absorbs minor engine movements. Its hardness (durometer) is tuned to offer a precise balance between flexibility and support. -

Inner Sleeve or Bushing

This component houses the through-bolt that secures the mount. It allows the part to flex slightly without losing structural integrity. -

Hydraulic Chamber (Optional)

Many modern RH mounts include a fluid-filled compartment to enhance damping, especially at idle or low speeds where vibration is more pronounced. -

Heat Shield (Optional)

If the mount is close to hot components such as the exhaust manifold or turbocharger, a heat shield protects the rubber from thermal degradation. -

Sub-Assembly Integration

The “Sub-Assy” in the name indicates that the mount may come pre-assembled with additional brackets or fasteners to ease installation and improve fitment accuracy.

Performance Characteristics

A high-quality RH engine mount must deliver consistent performance over years of use under demanding conditions. The following characteristics define its functional reliability:

-

Dynamic Load Resistance: Withstands stress from starting, shifting, and acceleration without cracking or collapsing.

-

Thermal Stability: Maintains flexibility and shape despite exposure to extreme engine bay temperatures.

-

Noise Reduction: Lowers the decibel levels of engine noise reaching the cabin.

-

Fatigue Resistance: Resists cracking, hardening, or deformation from long-term vibration exposure.

-

Corrosion Resistance: Withstands road grime, water, and engine fluids without rust or breakdown.

A properly functioning RH mount contributes to better engine behavior, smoother gear changes, and overall vehicle refinement.

Symptoms of a Faulty Right-Hand Engine Mount

As with other rubber or hydraulic parts, the Insulator Sub-Assy Engine Mounting RH is susceptible to wear over time due to age, environmental exposure, and operational stress.

Common signs of failure include:

-

Clunking or Knocking Sounds

A failed mount may allow the engine to make contact with the chassis, especially during shifting or over bumps. -

Excessive Vibration

Vibrations felt through the steering wheel, dashboard, or seats, particularly at idle or low RPM. -

Engine Movement

Rocking or shifting of the engine when revving or during gear changes. -

Misalignment

Abnormal belt wear or misaligned pulleys due to engine tilt caused by a collapsed mount. -

Visible Damage

Cracks in the rubber, leaks from fluid-filled chambers, or broken metal brackets.

Timely replacement helps prevent secondary damage to hoses, wiring, exhaust components, and driveline systems.

Installation Overview

Installing the RH Insulator Sub-Assy Engine Mount requires mechanical knowledge and may involve lifting or supporting the engine to relieve pressure from the existing mount.

Installation steps generally include:

-

Engine Support

Use an engine hoist or jack (with a wooden block) to support the engine safely before unbolting the old mount. -

Remove Obstructions

Remove any parts that may block access to the mount, such as air intake components, engine covers, or battery trays. -

Unbolt the Old Mount

Loosen and remove the mounting bolts from both the engine and the frame. -

Inspect Surroundings

Check the condition of adjacent mounts and components for wear or damage. -

Install New Mount

Position the new RH insulator mount, secure it with new or existing bolts, and torque them to the specified settings. -

Reassemble and Test

Replace any removed components and test engine stability by starting the vehicle and checking for excessive movement or noise.

Inspection and Maintenance

Though engine mounts are designed to last tens of thousands of kilometers, periodic inspection during routine services can help detect early signs of failure. Check for:

-

Oil contamination (which can degrade rubber)

-

Physical cracking or separation of the insulator

-

Signs of engine tilt or vibration under load

-

Unusual noise during takeoff or gear changes

Preventive replacement can avoid damage to other systems and preserve the vehicle’s refined performance.

Benefits of Replacing a Worn RH Engine Mount

-

Improved Ride Quality

Reduced vibration and smoother driving dynamics. -

Enhanced Engine Control

Prevents shifting or rocking that could affect power delivery or gear engagement. -

Longer Component Life

Protects axles, hoses, electrical connectors, and exhaust components from undue stress. -

Noise Reduction

Eliminates clunks, knocks, and low-frequency drone caused by metal-to-metal contact. -

Restored Structural Integrity

Maintains proper powertrain alignment for optimal operation.

Follow us on Facebook for more parts.

Reviews

Clear filtersThere are no reviews yet.